I am occasionally asked how to dovetail. It is a bit of a cheeky question and it would take me several months or more full time to teach this properly. Sometimes people seem to forget I am running a business.

I have been making dovetailed planes for over 25 years now and I still keep trying to improve my system. Another plane maker described my dovetails as made on the CNC and are very cold and clinical – is this how one would describe a precision job? Then guilty as charged.

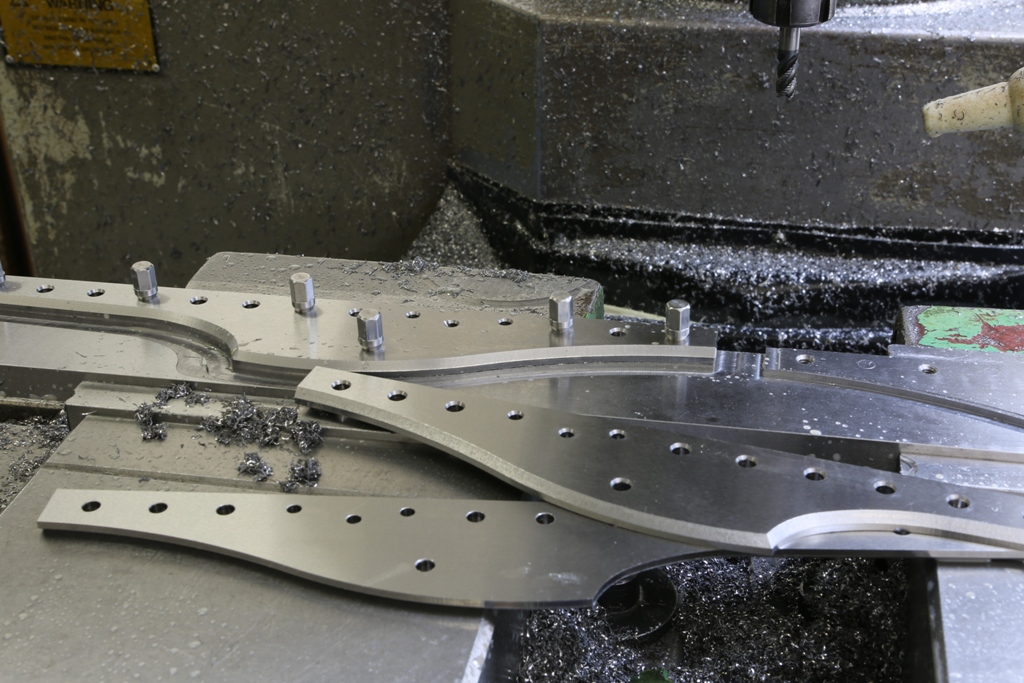

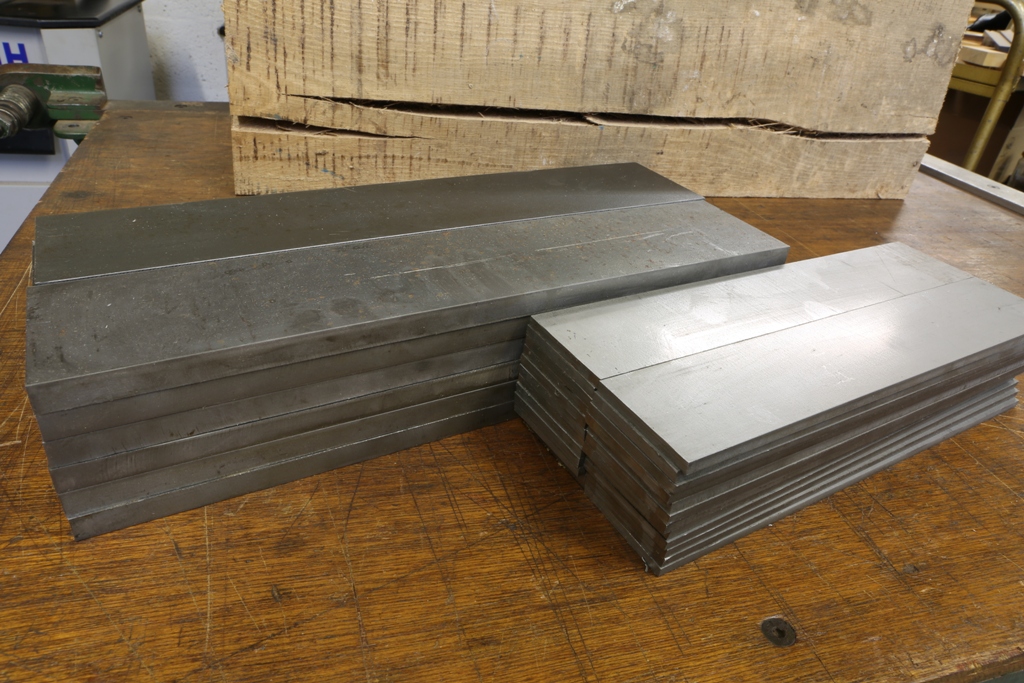

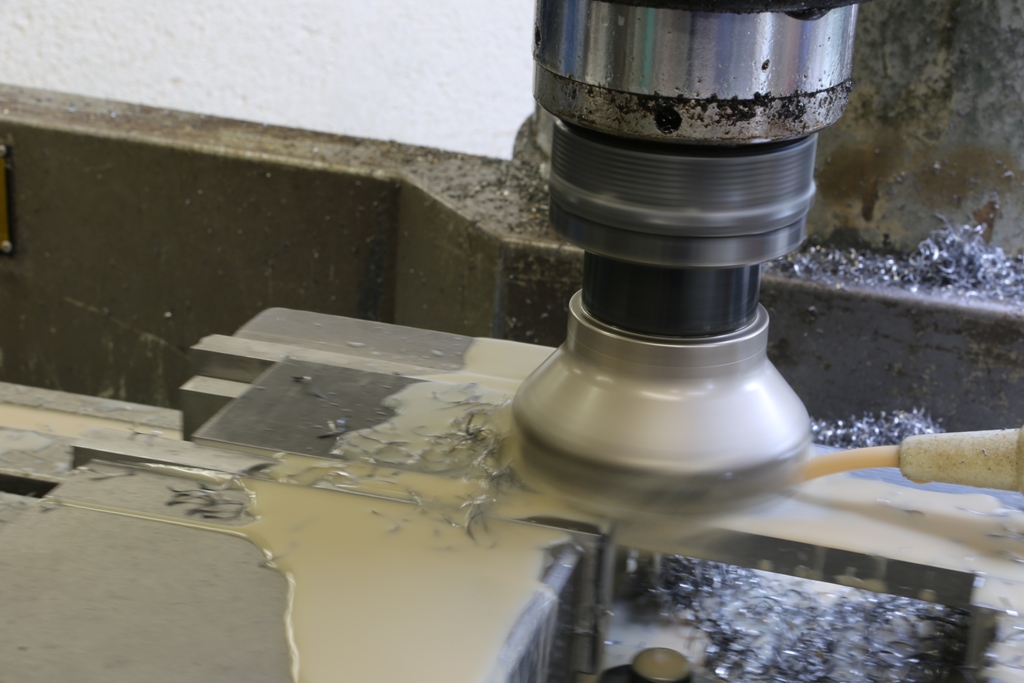

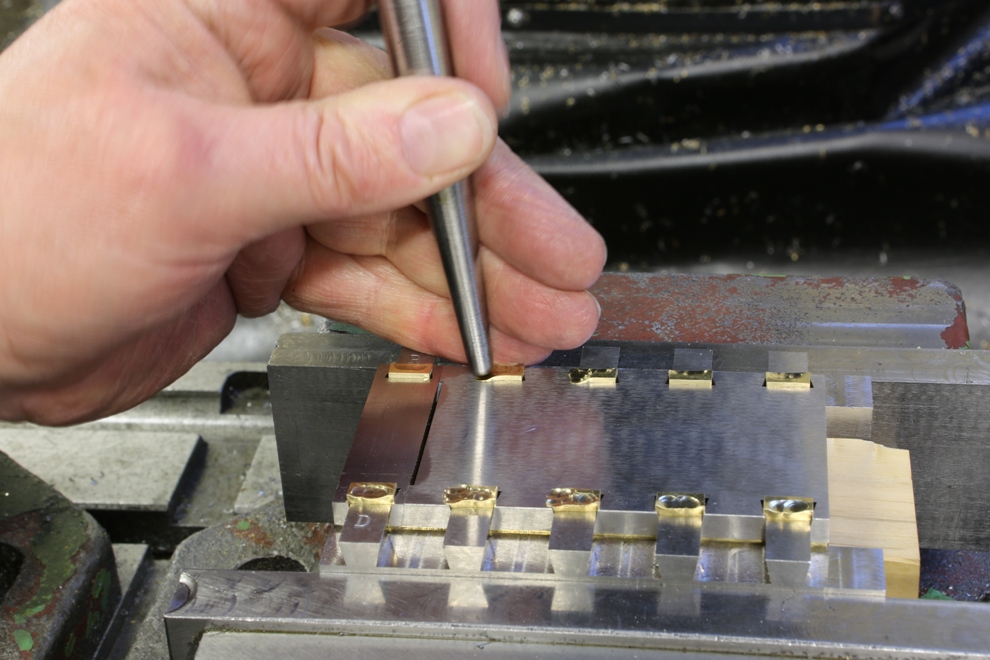

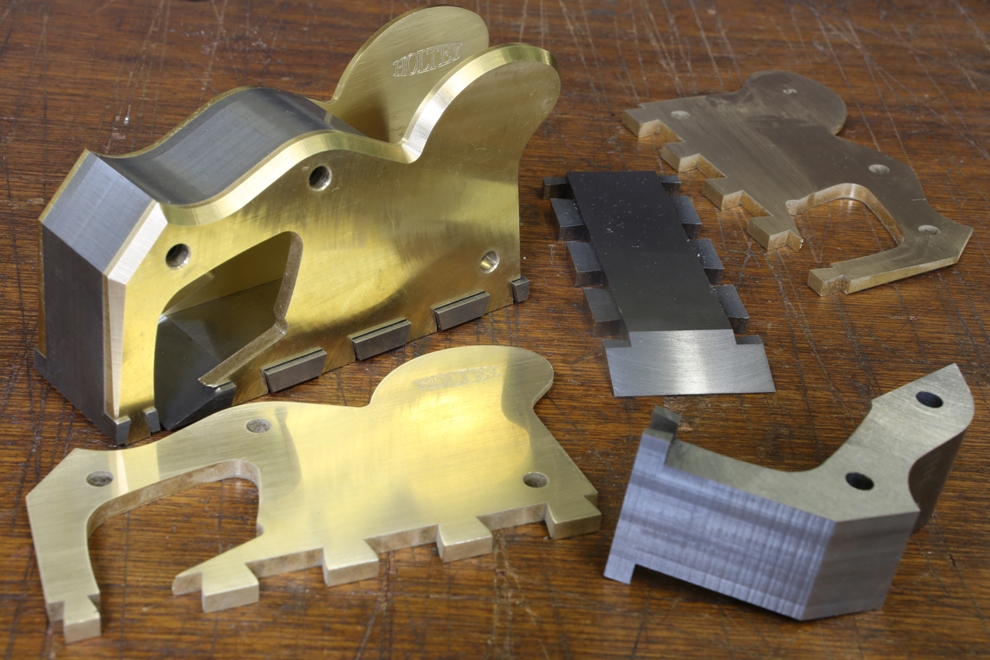

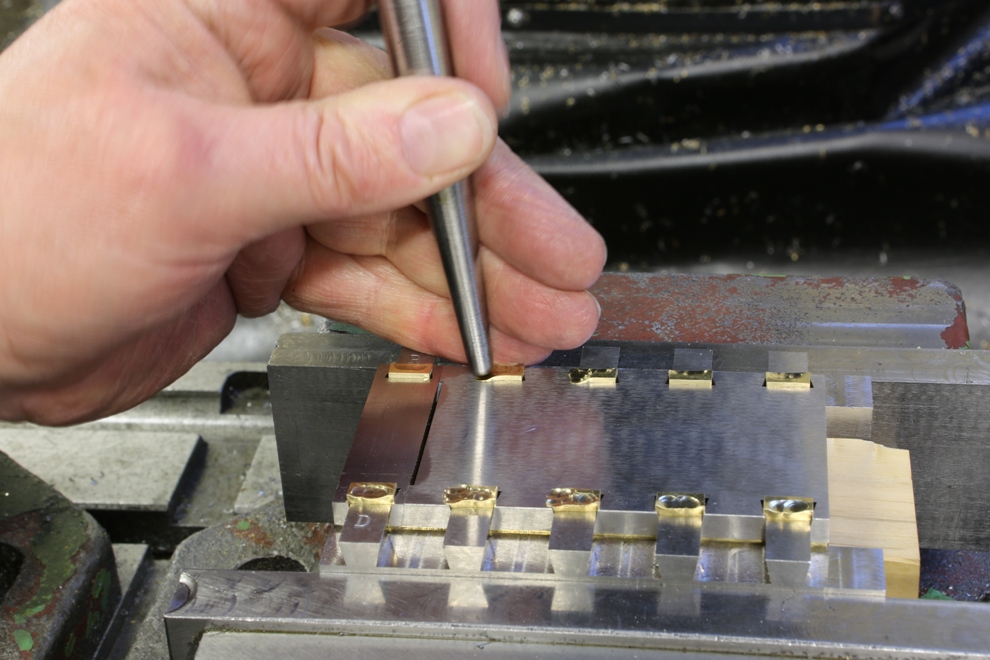

Here are some photos of part of the dovetailing process.

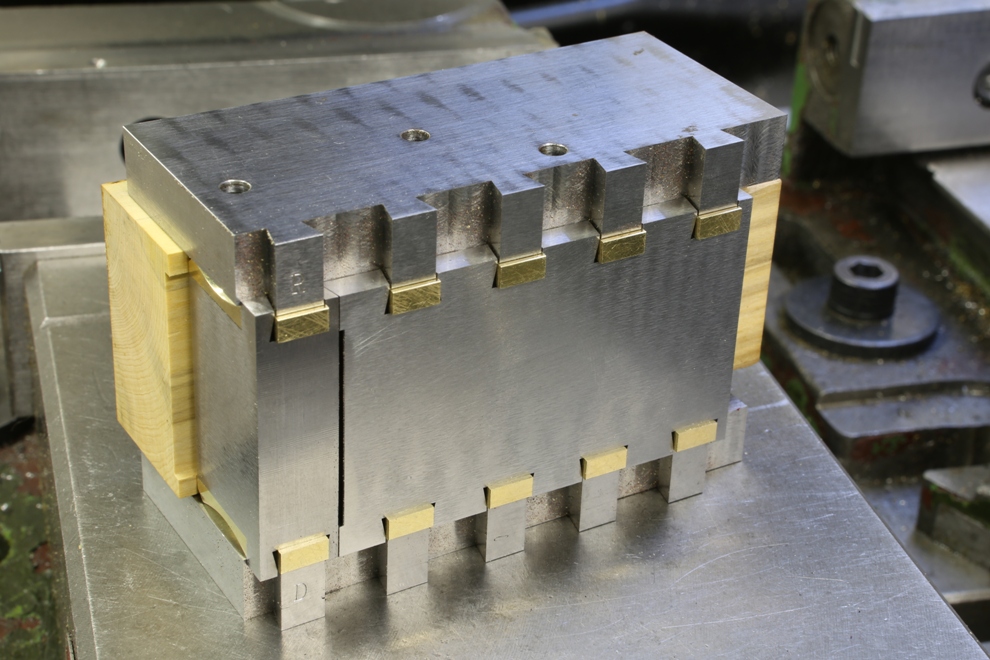

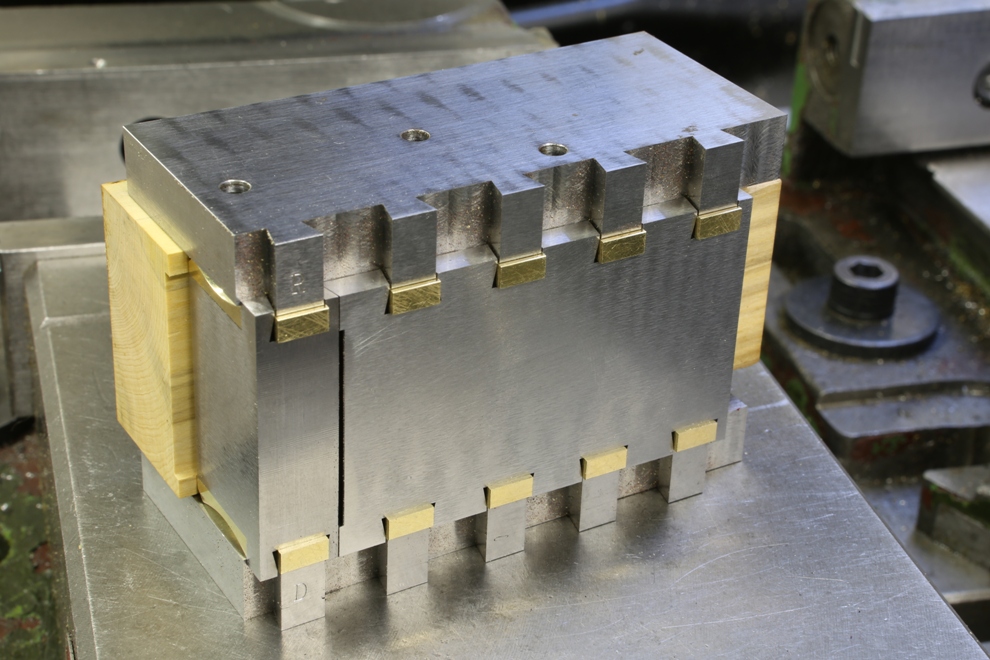

Sometimes it is frustrating that I have to do this much work before closing a plane up. The pictures above show a Boxwood spacer which supports the sides whilst peining the dovetails. Sometimes I use aluminium for this process but as I am only making 6 planes it doesn’t have to do much work. Also the sides of the plane will not be scratched when removing the spacer. A lot of work for a piece of tooling which will be discarded after six uses.

Showing everything in place ready for clamping in the vice. Note that the clamping plates support the dovetails as well. There is no movement and everything stays true to size.

This is the first stage of peining. You will see that the peining looks quite messy and untidy as I am stuffing the extra brass into the voids.

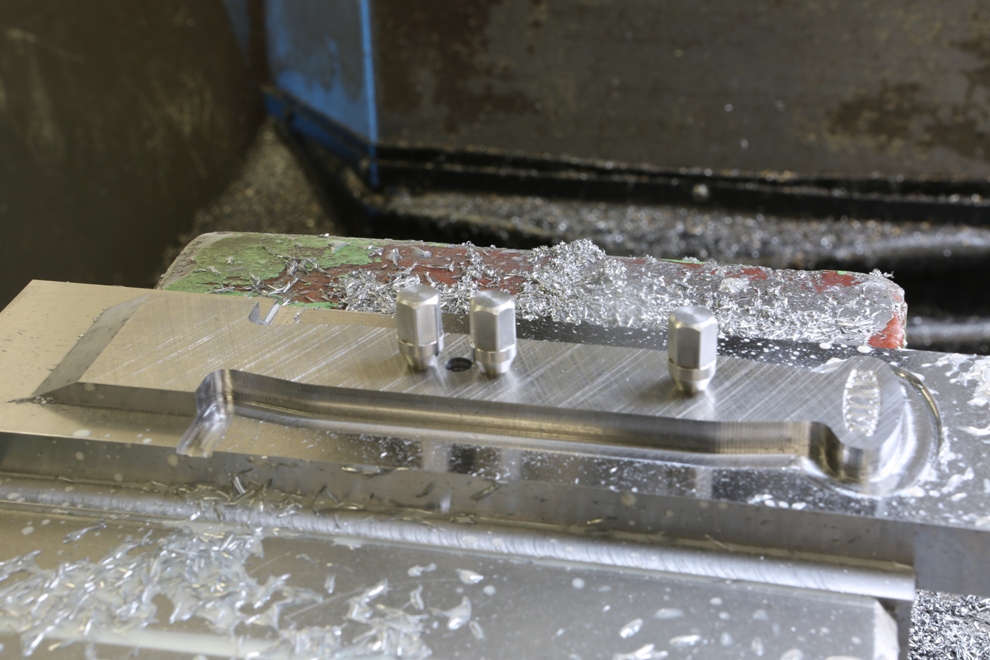

The last stage of peining the dovetails is the sides. Again the assembly is clamped in a precision vice with a spacer plate between the uneven peining on the underside so true reference is maintained.

The use of bimetals will show up any untidiness.

Easy isn’t it