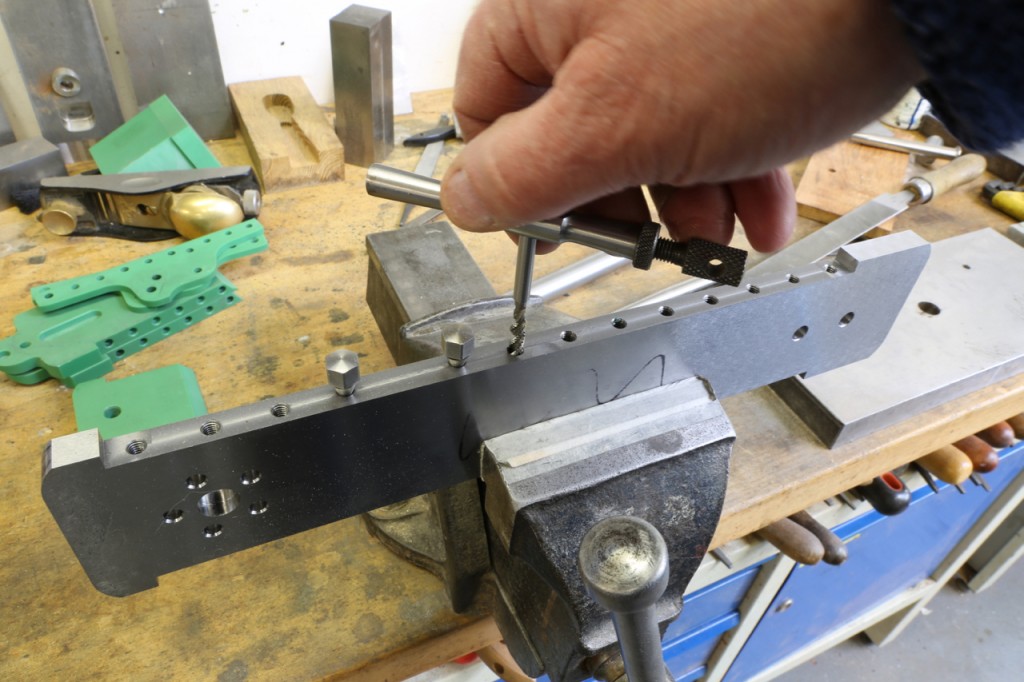

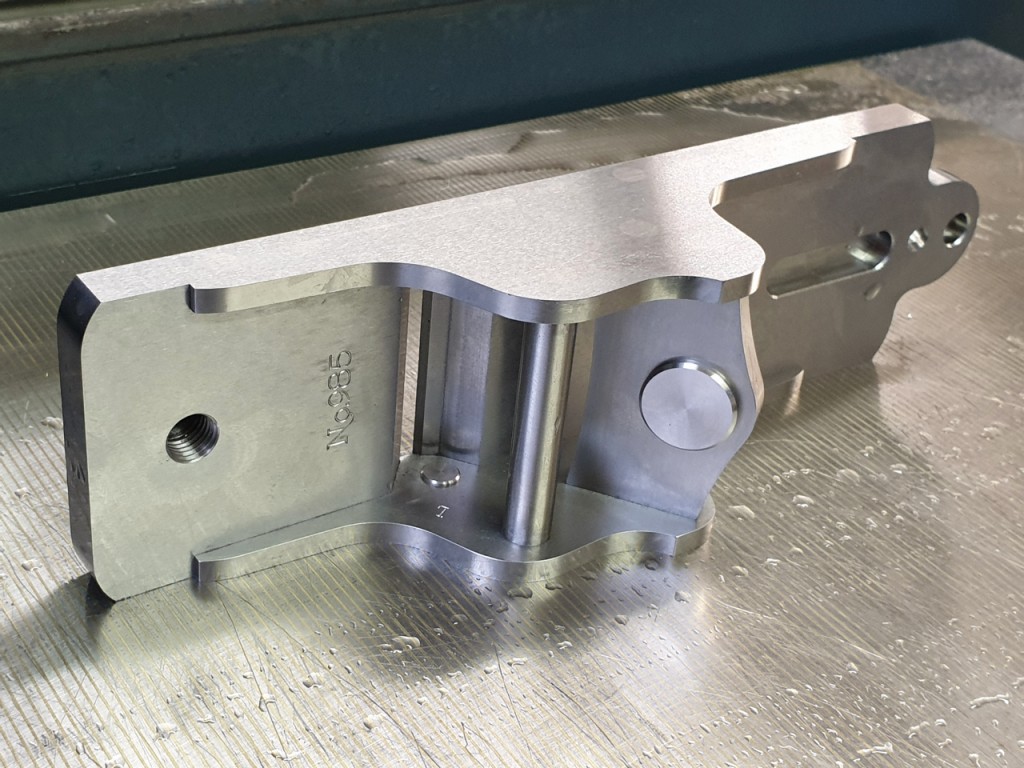

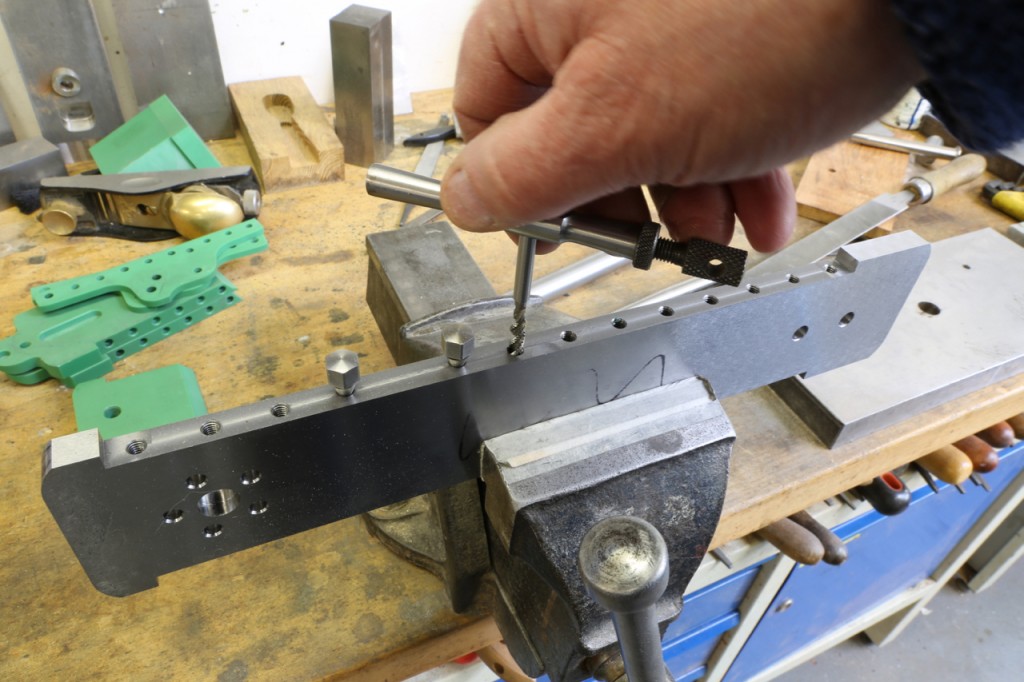

Unlike the No 984, with its in situ dowels, I have chosen to screw the No 984s planes. Both systems have their good points.

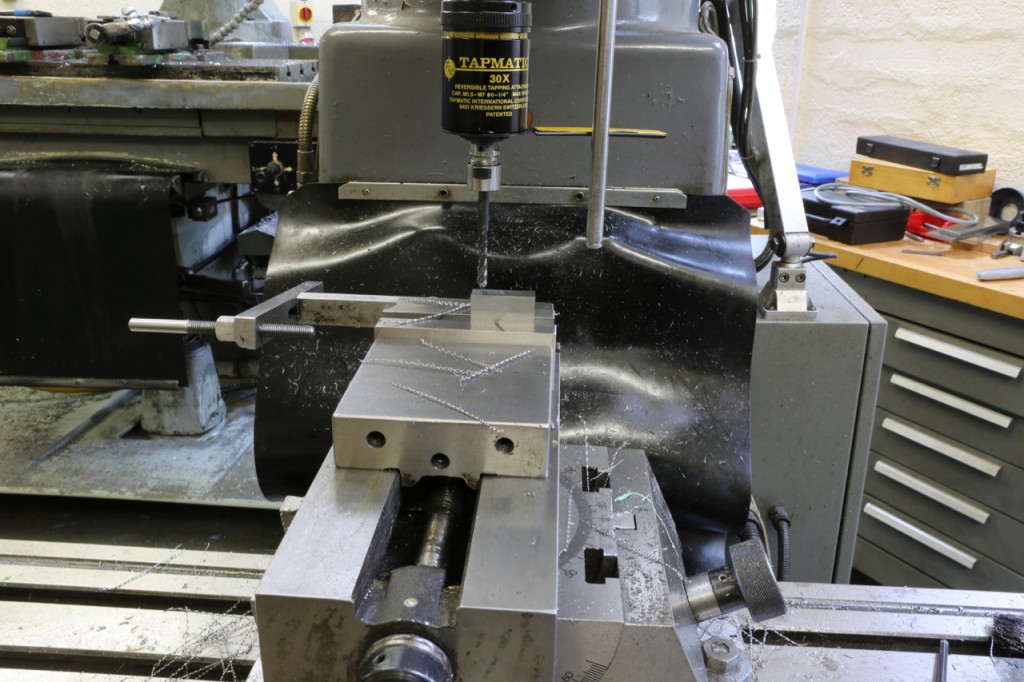

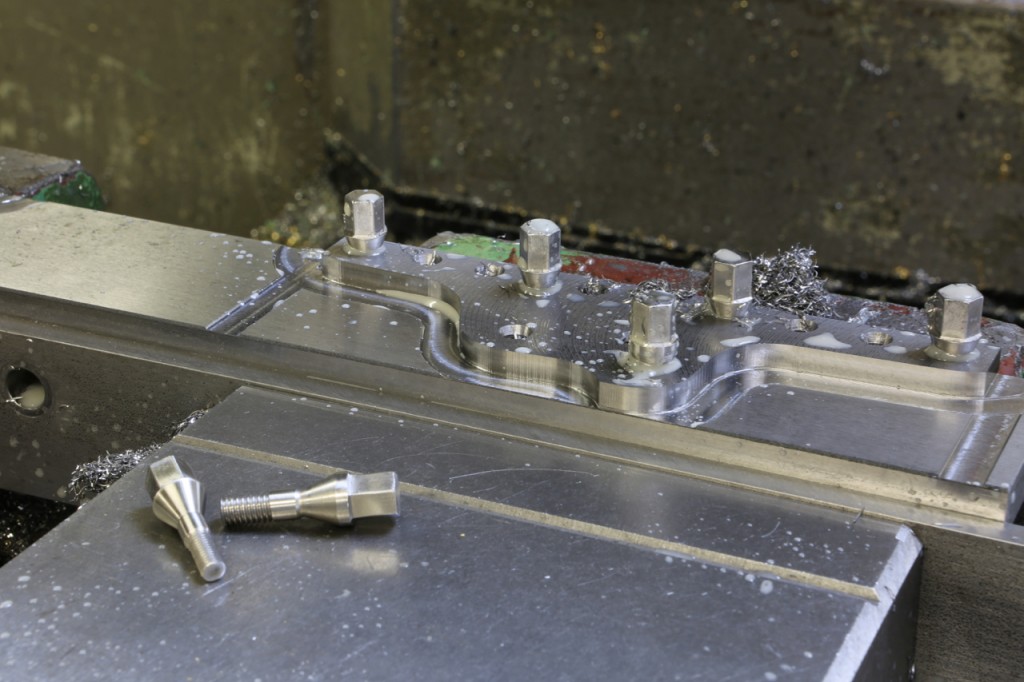

tapping on the mill with a tapping head never seems to be enough so I have to go over these again by hand. It is important for the fixing bolts to run free. I have to assemble and dis-assemble dry quite a few times. When it comes to the final assembly it is essential that there are no problems as the bolts will be going in with torque control and permanent locking compound.

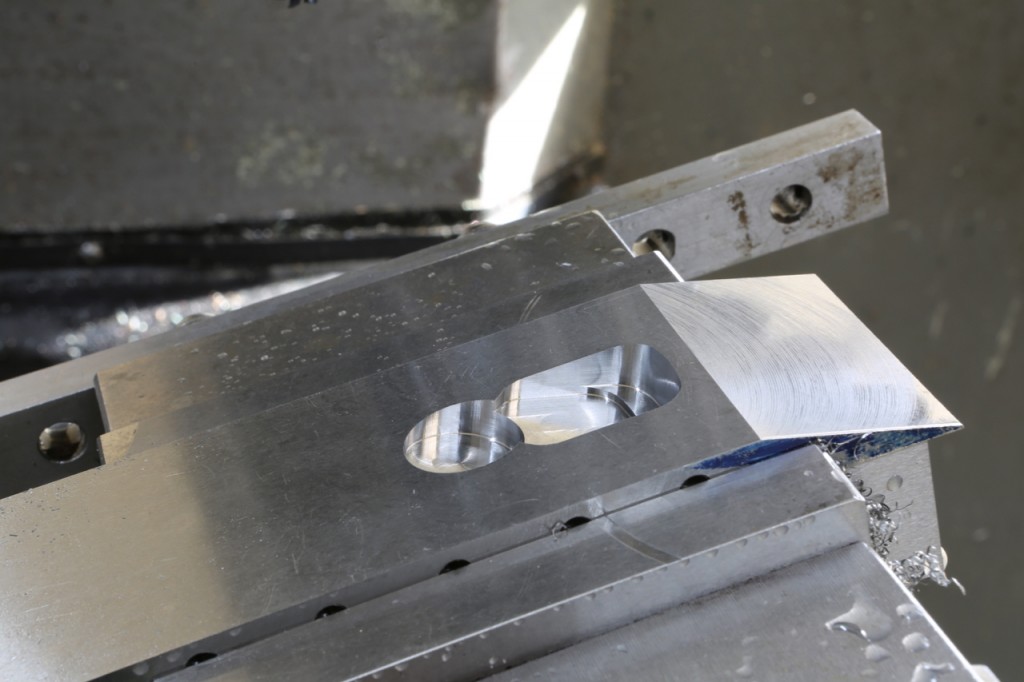

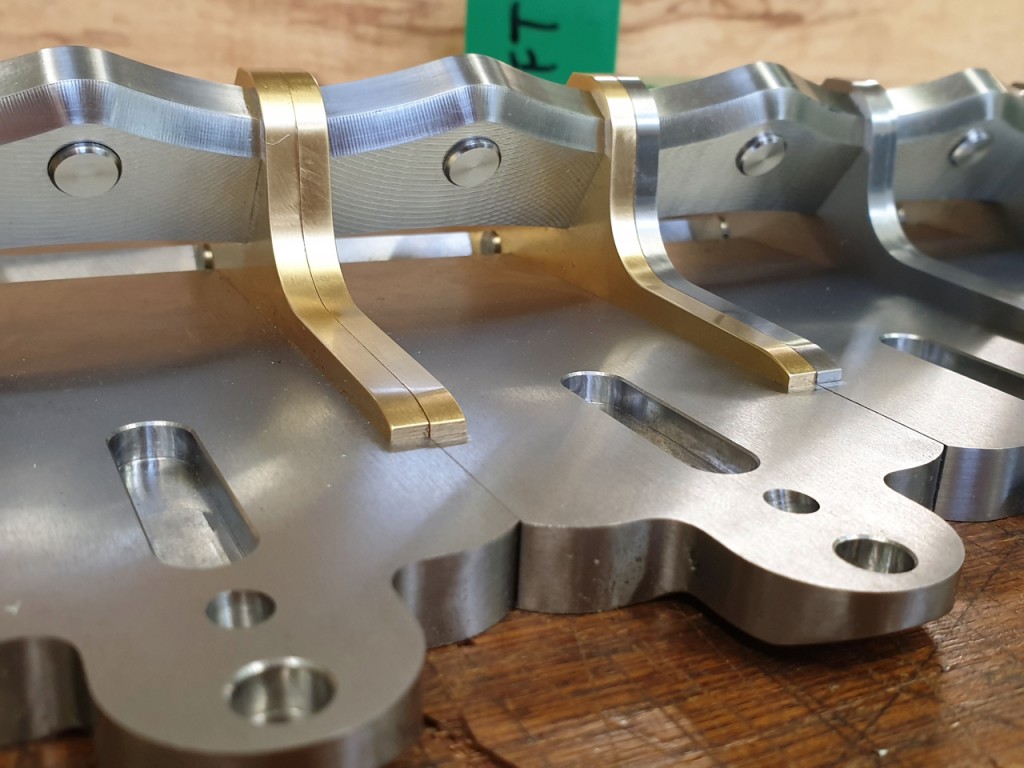

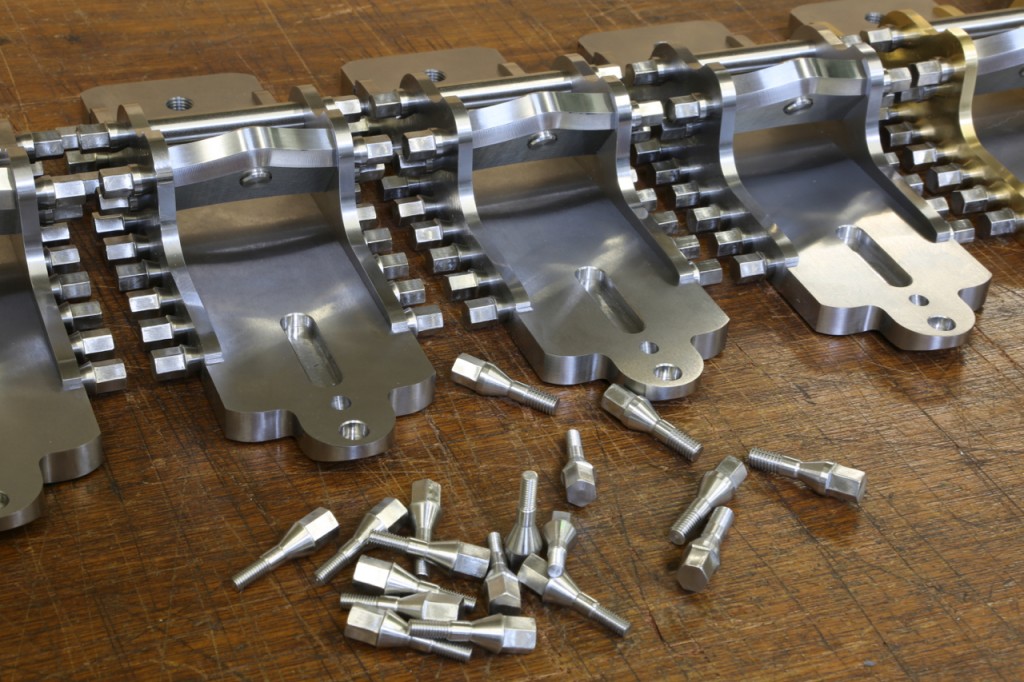

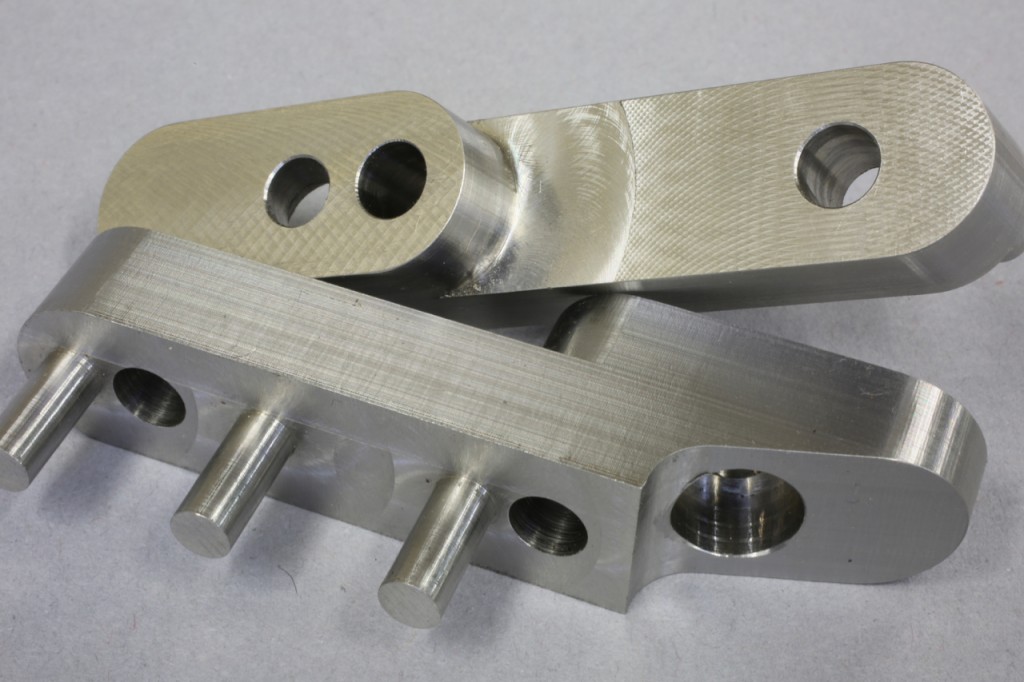

With all the milling, grinding, forming, drilling and tapping done I am half way with the bottoms. These will now be set aside until I have completed the sides – next job.