This is the start of a new version of the No 984 panel plane. It will be 12 ½” long with a 2″ blade. There will be a slight variation in styling.

February 21, 2020

September 18, 2019

September 14, 2019

Workshop Blog no 29 – No 985

The bolts have been thread locked with Loctite 270, so things should be moving along very quickly now.

May 23, 2019

Workshop Blog No 24 – No 985

Slipping behind on postings as I have been so busy.

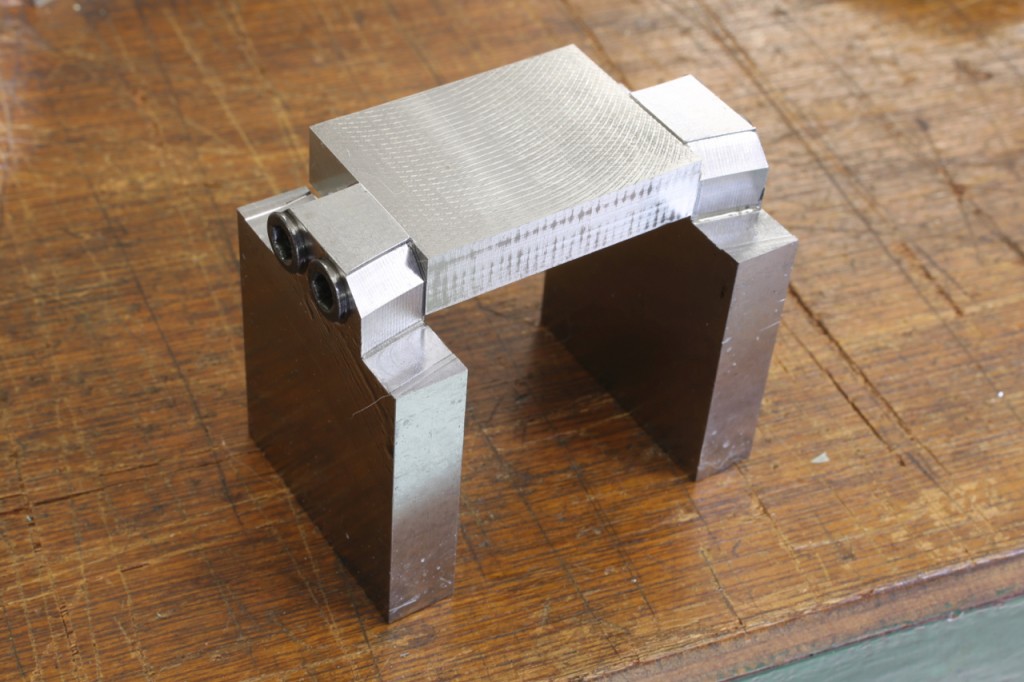

As a follow on from last posting on upper blade bed, the design is similar to the one used in my No 982. I didn’t want to go this far but I can’t think of anything better. It is certainly solid if nothing else. You just have to bite the bullet and get the work done.

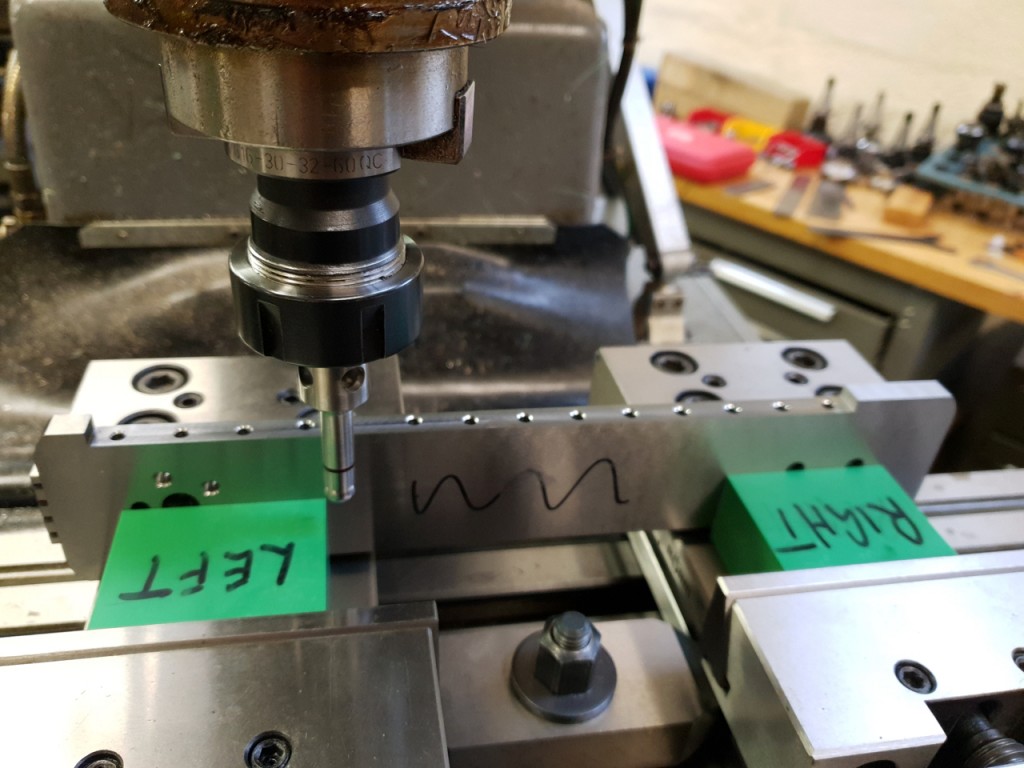

This picture shows the tooling required for the last part of the operation after much preparation. As you can see this kind of tooling doesn’t come cheap. I always keep plenty of backup – if I get a tool failure I want to be able to change it immediately.

April 4, 2019

March 22, 2019

Workshop Blog no 19 – No 985

One of the things about the smoothing plane is that it is for finishing only and this is better achieved by keeping the plane as short as possible. In the past a smoothing plane was a smoothing plane and usually about 7 1/2″ sole length, obviously here we are not trying to straighten or flatten the wood, this means very fine cutting. You have to follow into imperfect surfaces which bigger planes wouldn’t reach.

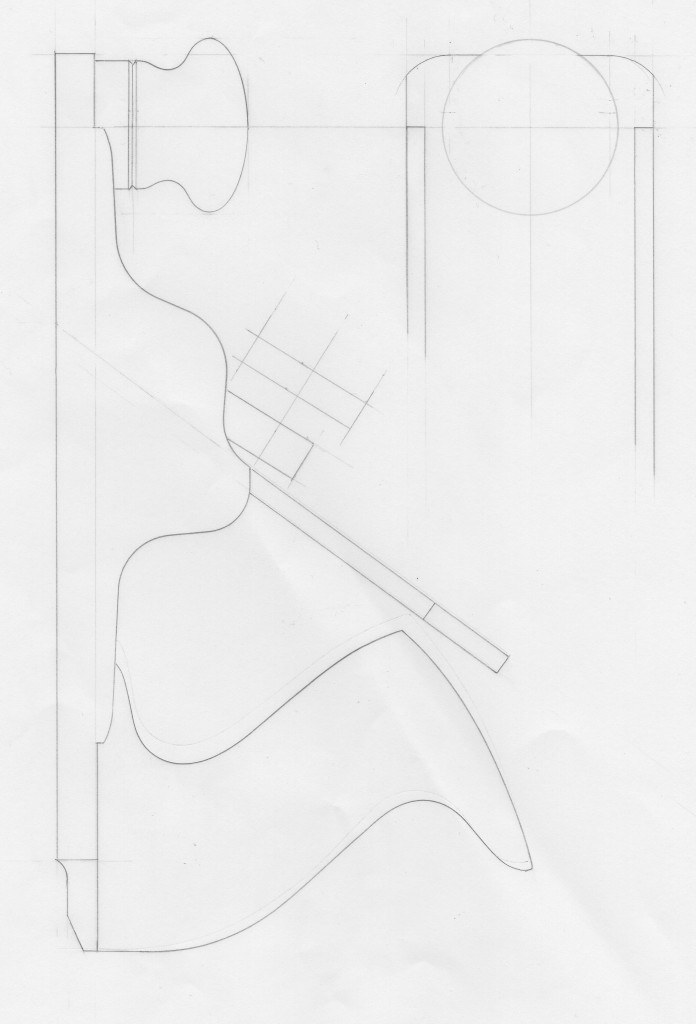

For this plane the adjuster had to go. I wanted a full rear handle but had to lose some of its height, which is fine as most people are happy with just holding with three fingers leaving the index finger to rest on the side of the blade for orientation and feedback.

I have had to make a compromise on the length of the sole as I could not get down to 7 1/2″ but settled for 7 7/8″. One of the reasons it was hard to keep the length down is that I managed to retain a 50 degree working angle on the rear tote which makes the plane much more comfortable to use. Not to be confused with the blade angle which is 54 deg.

As mentioned previously the plane is in 416 stainless steel and the wood used for the handles is the same as the No 984 – Dalbergia Stevensonii. This wood has a nice texture, hard, dimensionally stable and retains its contrast and colour.

The lever cap and thumb wheel are in a similar design to my No 984 plane also. The handles are extremely rigid and show no sign of their fixtures (another example of hidden work). As my blog progresses you will see more about them.

This is a designed and engineered tool. I feel that I am fulfilling my object of always surpassing the standard which has gone before.

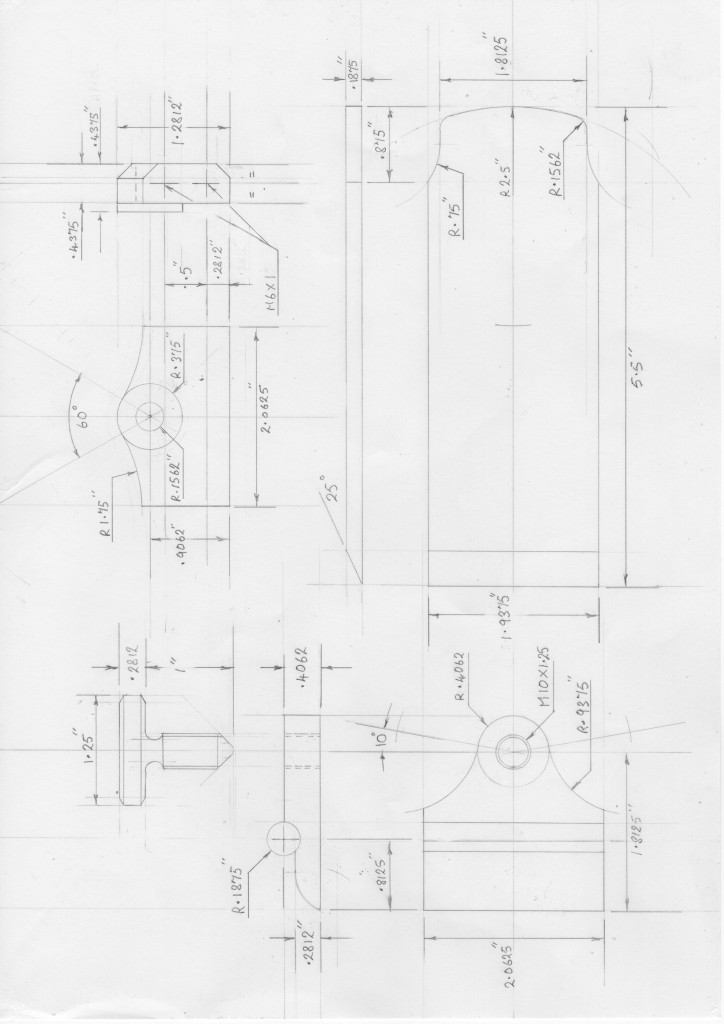

I thought this was a good stage to let people know what this plane looks like. I have added two drawings though I do get paranoid about being copied.

March 12, 2019

Workshop blog no 16 – No 985

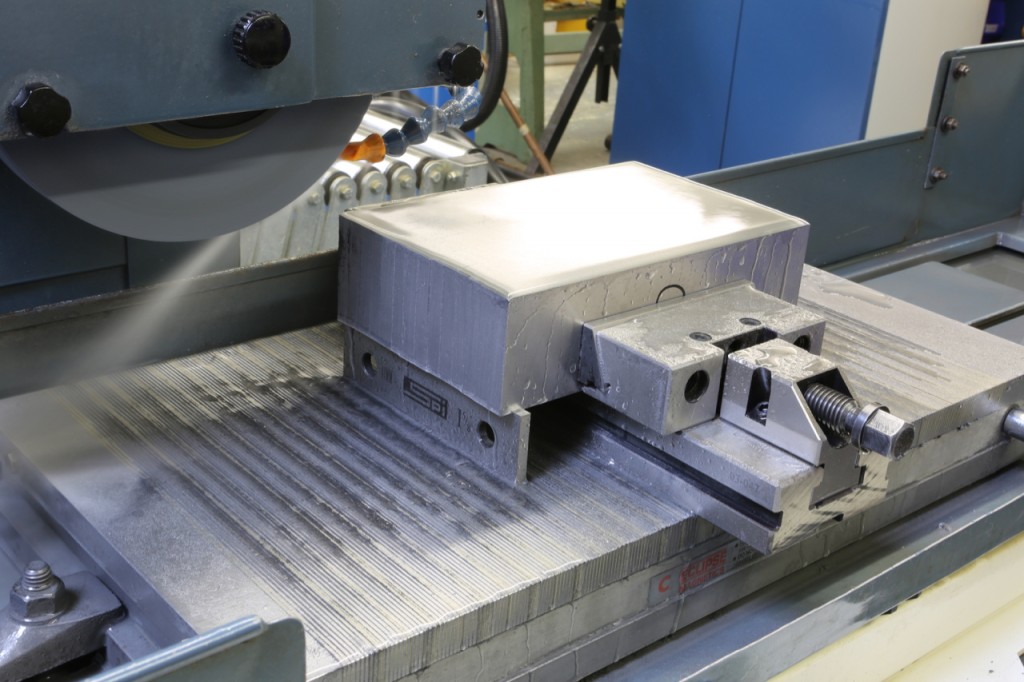

Lots of work and very boring but worth showing. Here are the No 985 bottoms after milling from stock, they go on to be precision surface ground on four sides. This is to maintain sectional precision. The rest of the work to follow is on my CNC mill.

All the parts are clamped together after milling the edges so they can be rotated for the opposite side without any disturbance.

I think I am the only person on record to work to this standard. It might be over the top for some but the achievements speak for themselves.

March 1, 2019

Workshop blog no 14 – No 985

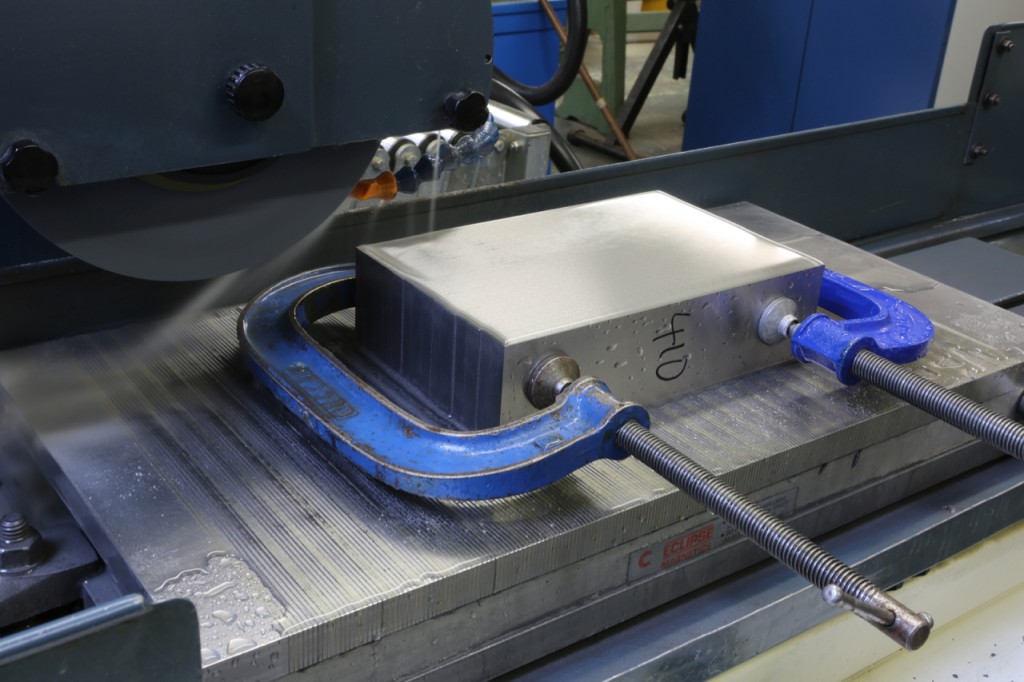

I was hoping to get a little bit further than this but too many interruptions. I have finally made the decision to cut up my 416 bar for the bottoms – scary, can’t go back now. But I have been procrastinating for long enough. Especially since the bar cost £1100. Like most of my materials it is a rolled bar which needs to be planed just as you would with a piece of wood but harder work in stainless steel.

This is reducing the bar down to its finished size. I am looking forward to the rest of the work.

February 24, 2019

Workshop Blog no 13 – No 985

It is always a nice sight to see a job finished, a nice picture for the album. Don’t know how the brass got in there. All the stainless is 416, imported at great expenses from USA (new 25% tariff and it was already expensive).

I am making a point of keeping plastic test samples – much cheaper to mess up – and it is nice to have something on record.

All my tooling is state of the art, not much carbon steel or HSS in my cupboards.

February 23, 2019

Workshop blog 12 – No 985

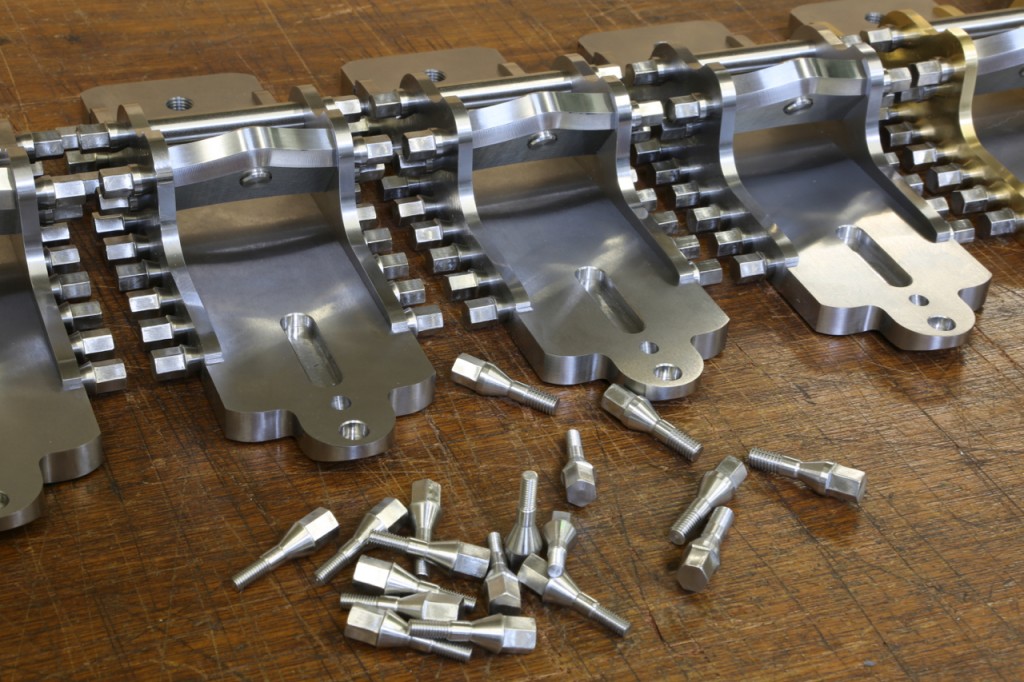

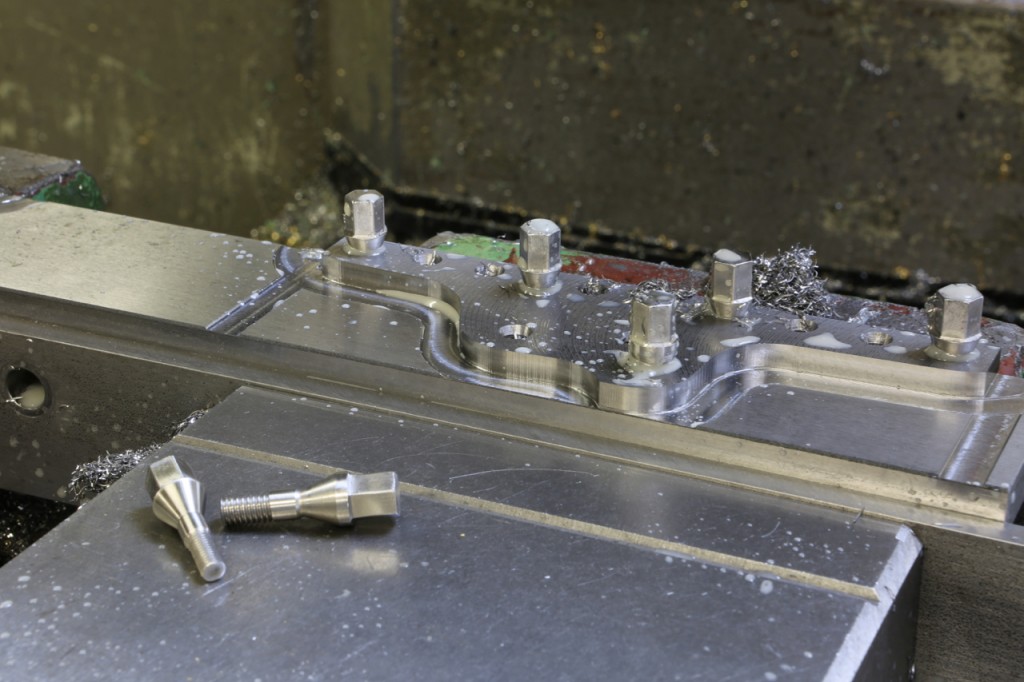

The last side of the No 985 plane. The fixture screws (custom made of course) are also going to be used in the fabrication of the plane. They will be bedded in a locking compound.

I have flitted backwards and forwards between this system and the in-situ riveting – they both have their plus points. Same quantity of work with either system. But working with this system puts less stress in the construction.

As you can see from these jig screws they have a precision shank for true alignment.