Mistakes – what is a mistake?

There are those that will always deny making mistakes and there are those that can keep smiling when they have made one as they have thought of someone to blame it on. So many projects can go off course along their journey, or find that the goalposts have been moved. Those with the creative thinking processes, for good or bad, can always find a solution; then only count its merits.

In the case of the No 10 plane, and its simplicity, there seemed nowhere to go wrong, but to be 100% sound in my mind I need to alter some of its dimensions. Having slept on it I have decided it is folly to rescue anything I am not completely happy with. This doesn’t sound much – just need to remake the sides and procure some new infill material. I have come too far now to take any risks. Reputations can’t be compromised. Luckily I haven’t had to use the reject bin too much over the years – it is due to put on weight.

Apologies to those waiting for their planes but as you can see from the blog below there is still steady progress.

—————–

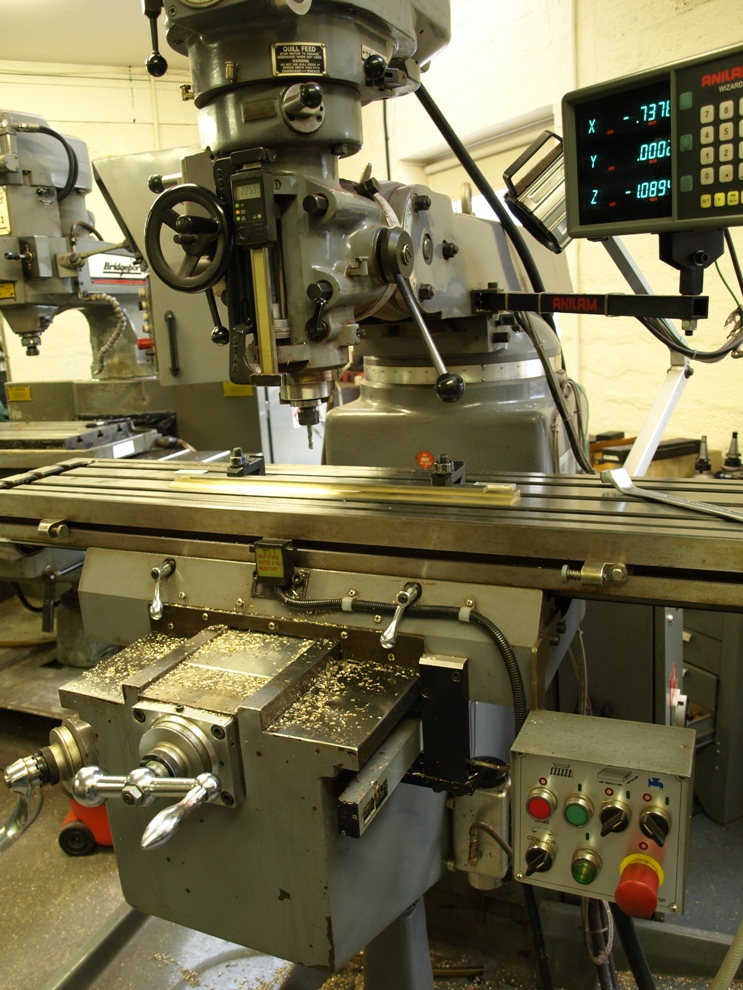

In the making of my planes I rely quite a lot on a manual mill. So far throughout the making of these planes the machine has been in constant use.

There is a lot to be said for a good quality manual mill with a DRO. The skill is in setting up and operating these machines and along with essential hand working I am able to achieve standards that are impossible to achieve with hand work alone. In my cabinet making and joinery days there was always a division between machinists and hand workers. Why? I have always wanted to be involved in every aspect of the project from initial thought to the finished item. This is why I never outsource any of my work.

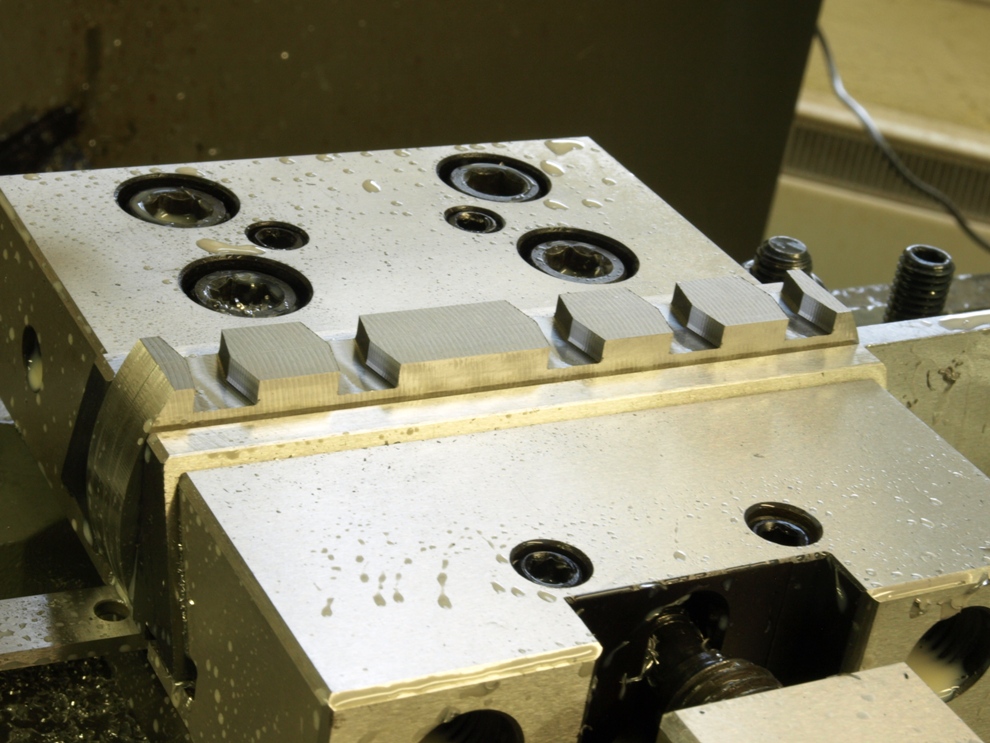

For some reason I have never looked forward to doing this stage of the work in stainless steel in spite of all the experience I gained with the No 98. With a good plan of attack stainless steel will lend itself to quite a lot of cutting and manipulation. There are some that shake at the knees at the mention of stainless steel. This picture shows the first stage of roughing out for the dovetails and in the following picture it shows the milling in the final stage with a forming tool. Note that the bottoms having the compound dovetail so they are made in mirrored pairs to simplify things.

Dovetails finished with all the mess cleaned away.

(more…)