More later ….

January 11, 2016

November 30, 2015

Window to my workshop No 99

LEVER CAP

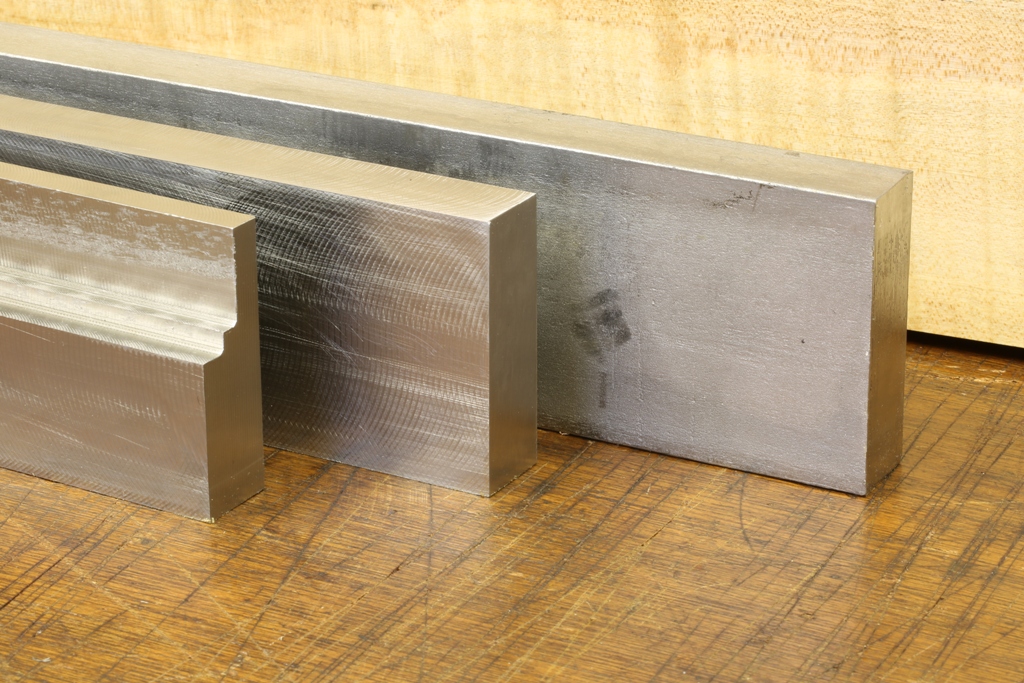

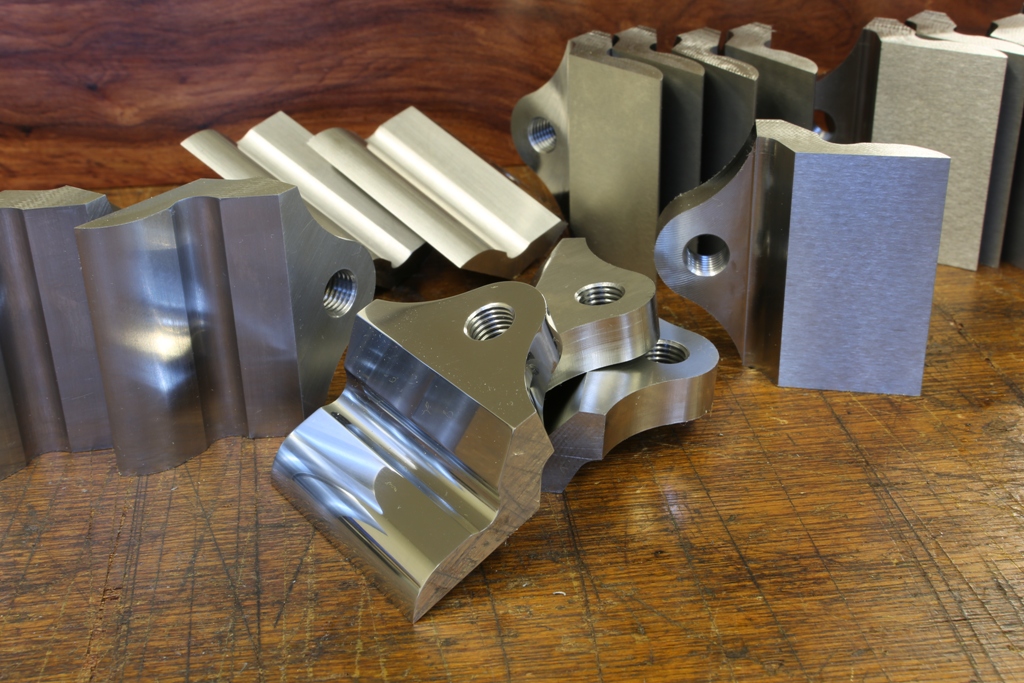

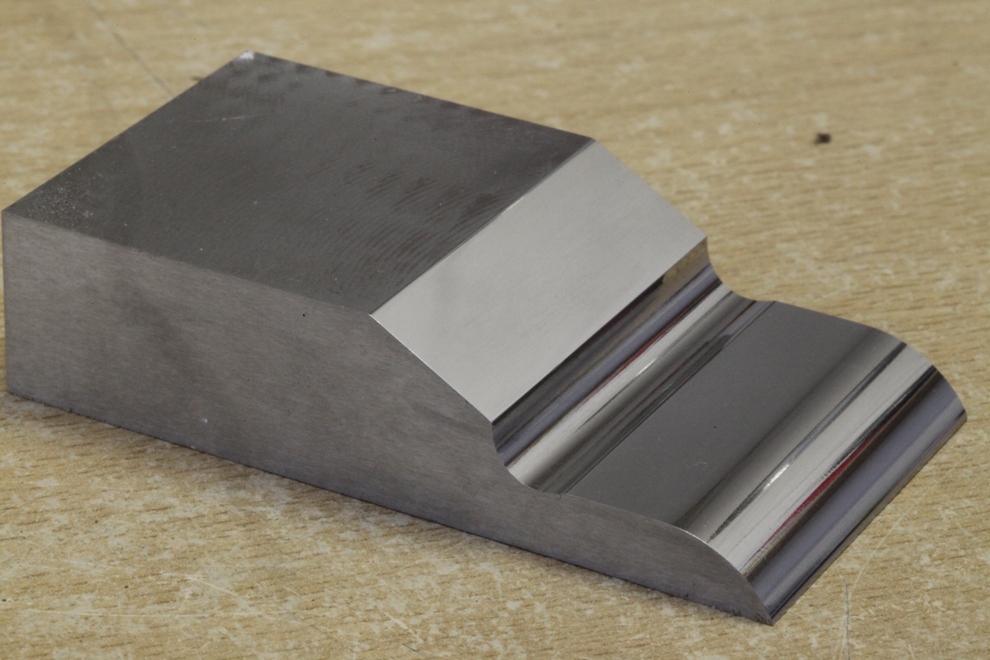

As with many of my components these are fabricated from solid bar. The three pictures shown below are starting from a raw bar, removing the excess and shaping then the finished product.

This has probably been one of the most labour intensive of all the parts. Now that they are done, with the exception of polishing (which is no mean feat), I am very happy to move on to the thumb wheel and pressure pad.

Update: A modification has been made for ergonomic purposes. An additional chamfer has been added in case there is any contact with fingers or knuckles.

September 16, 2015

Window to my Workshop 97

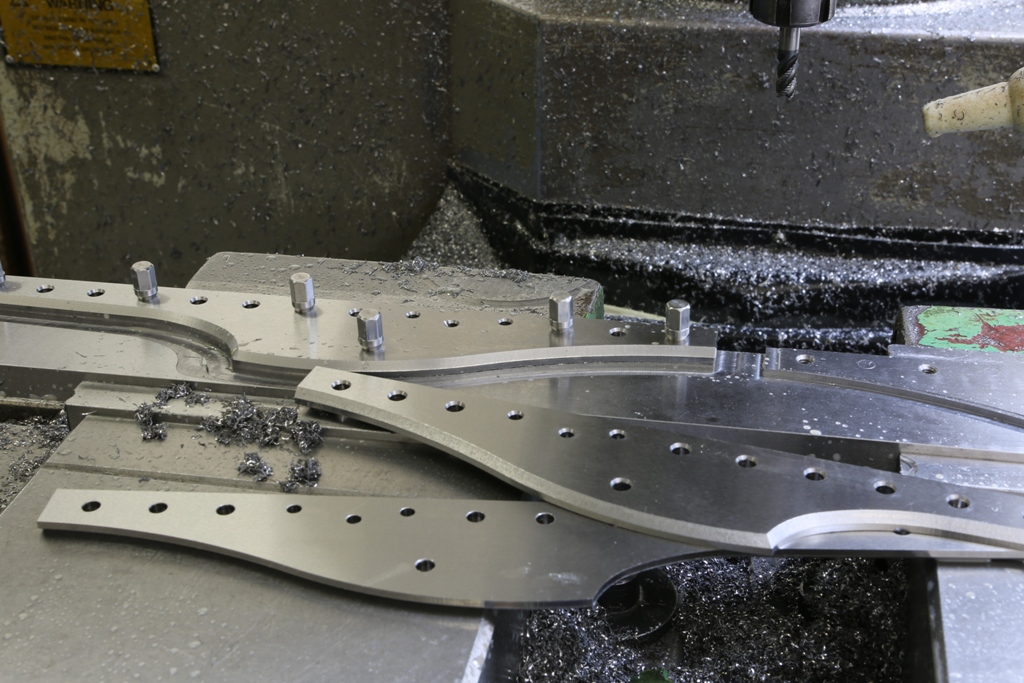

Sorry for the long gap, and probably a few photo opportunities missed. Now on to the bottoms of the No 984.

I had to make many visits to the drawing board to finalise the drilling for the handles, as I felt paranoia was setting in and a lot of double checking and tweaking was needed here. As you can see I have five holes to receive the 5 mm integral rivets for the front bun fixture. It may look a little excessive but I have seen what happens if a plane is dropped and lands on the bun. The original No 98 had three rivets. Four wasn’t right but five just seems to be correct. I always work in odd numbers for some reason. Funnily all office chairs have 5 feet.

For the rear tote I shall use 2 x 6 mm rivets, which are integral to its chair. This is one area that I have thought long and hard on, making this fixture as tough as possible. It is very limited by its parameter of being an open handle. This arrangement will be as strong as you will ever need. In the event of any impact the handle will be the first thing to break – so best not drop it – but it is wood after all. The handle can be replaced. With these two holes I am now committed, the rest of the handle will be tweaked a bit before I start.

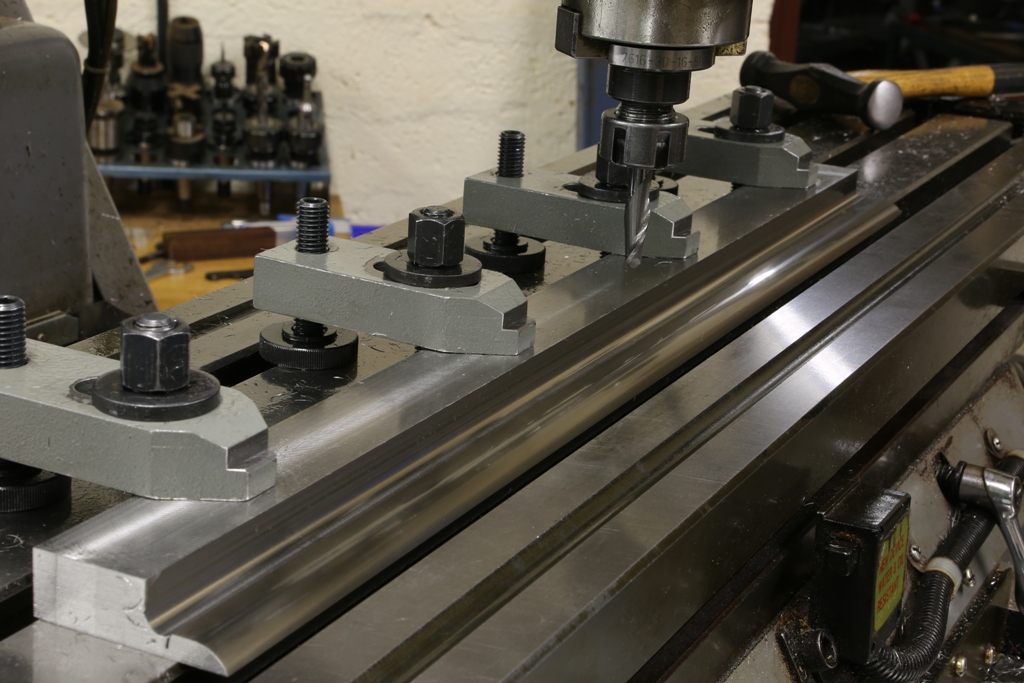

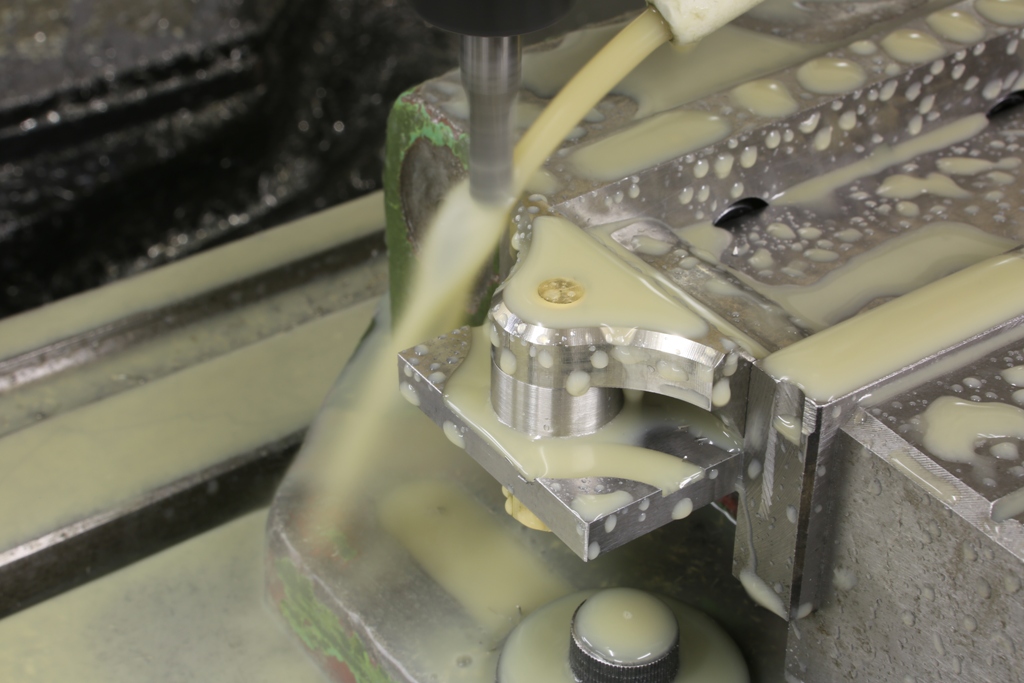

This is my holding arrangement for the integral rivets on the bottom of the plane. This was my second attempt, as I was not confident with the rigidity of the original arrangement. The setting up is where most of the work takes place.

With all my milling and drilling I always use the very best tools available. These rivets are cut full depth in one go to get the most use out of the cutter. This first cut is taken with a ripper which will cut the rivets slightly oversize and then follow up with a finishing tool, which will size and texture the rivets. It takes a lot of trial and error to get the optimum spindle speed and feed rate. The best instruments for this are my eyes and ears. It has taken me a long time to perfect this and these are the last planes just when everything is coming together.

The last operation with the rivets is applying a very small chamfer which helps to prevent any splits forming whilst peining.

The riveting finished.

August 12, 2015

Window to my Workshop 95

Since the last posting it has been a bit hectic with family visiting. Also I revisited the drawing board a few times as I wasn’t happy with the side profile. I have re-contoured and re-programmed several times until now I am happy with the profile.

These are a few pictures of the current progress.

Next is polishing of the edges, which I love soooo much.

July 17, 2015

Window to my Workshop 93

The blades arrived back from heat treatment and after many hours grinding and polishing they are now finished. Just packing them in oiled paper until the planes are ready.

The hardening is the only thing I outsource. Everything else is made inhouse.

July 13, 2015

Window to my Workshop no 92

One of the boring sides of this detail. It is no simple polishing job as the valleys formed by the mill are very hard to smooth out.

It is a case of starting with a coarse abrasive and working down to 1200 grade and then I wrap a piece of denim cloth infused with metal polish for the final polish.

That is a reflection of my magnetic tool rack which looks like a row of vertical scratches.

It seems odd doing polishing at this stage but it is the sequence which I choose to do the work in which gives me the finish. When all the riveting and adjuster recessing are complete I can surface grind the inner parts so everything is sharp and pristine.

Somebody on a forum described my work as being clinical and having no soul, maybe he is right and it is dammed hard work to keep it up ![]()

June 23, 2015

Window to my workshop 89

As I have said on my web page the No 984 panel plane is to be my last. This is the beginning of the promised blog. I have been a bit slow starting as I have been busy with stock sales and many enquiries. Thank you very much for all your nice comments – I am not actually retiring as most people I knew retired and died, I will keep up the coffin dodging and I have many other things to do. These No 984 planes will keep me going for about 3 months.

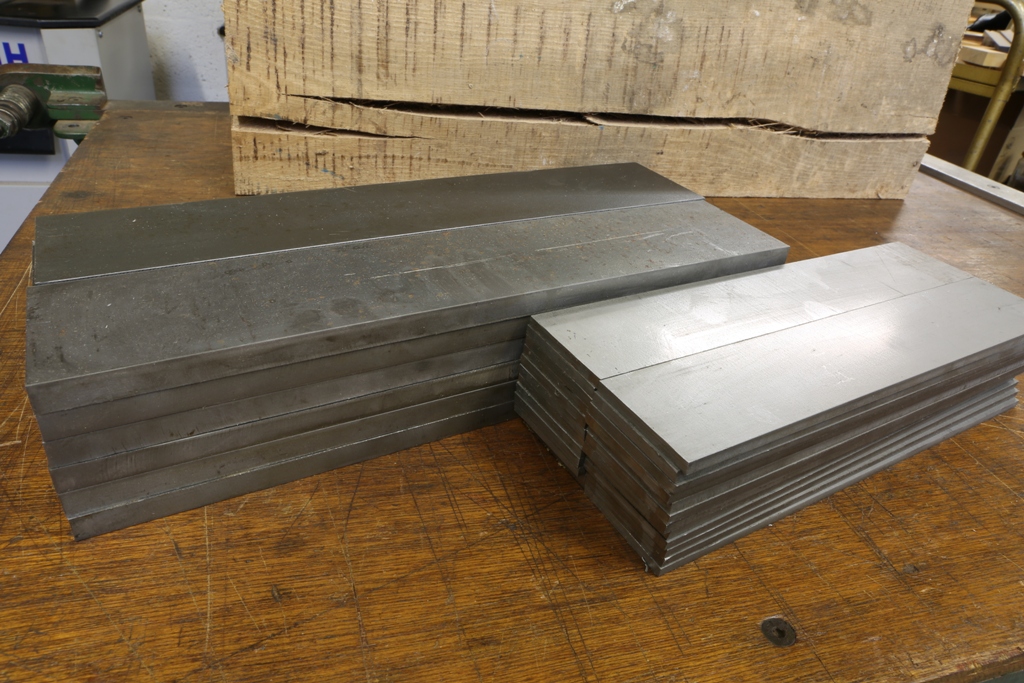

This is the 420 stainless steel that I am using for the bottoms and sides of the plane. The plan is to start knocking some weight off them. I am trying not to let the weight of the finished plane go over 3 kilos. All surfaces will be milled and ground. The steel that I have here is enough to make a limited batch of 12 planes.

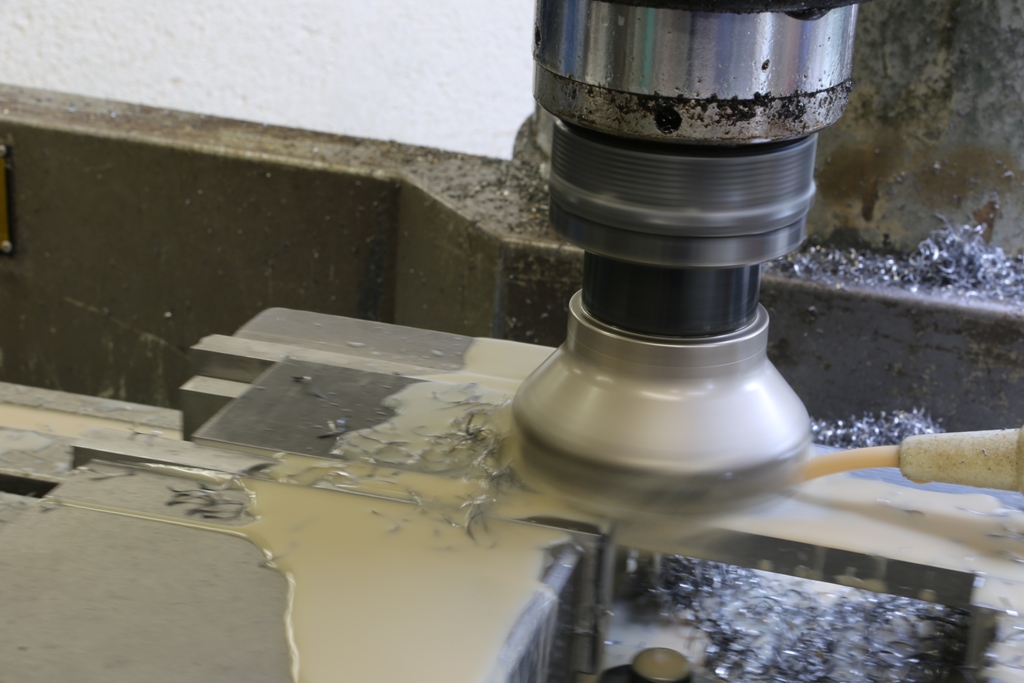

Here begins the slog, there is a lot of material to come away. This picture shows a bottom starting out 12 mm thick and it will end up just over 10 mm in the finished plane.

December 2, 2013

Window to my Workshop 75

November 11, 2013

Window to my workshop 74

As this lever cap has taken a very long time to make I thought this picture, of it not even half way completed, tells some of the story. The milling, grinding and polishing has to done in sequence to achieve the finish I require. It will be a complex shape when completed.

October 25, 2013

Window to my workshop 73

After several weeks of design, trial and tribulations, the thumb wheel in stainless steel is finally complete. New designs and ideas are always time consuming.

This picture shows the thumb wheel inverted and assembled with the floating spherical washer (the washer does not appear to be central on the photo as it is floating). This works with the matching spherical depression in the underside of the thumb wheel like a ball and socket; evenly spreading the load over its area, helping to eliminate any lateral movement on the blade as you tighten down on it. It also helps to evenly distribute the pressure throughout the blade bed reducing body distortion.

These are the three components making up the thumb wheel. I have changed the grip arrangement on the thumb wheel and screws. I dislike the fact that a lot of knurls fill up with dirt. Aesthetically I find this method, though labour intensive, is more pleasing and feels comfortable on the thumb/fingers.

I would like to emphasise that, as always, all my components are hand made, in house.