Final tweaking and polishing before assembly

Once assembled there is no access

Progress on my A28 Chariot Plane

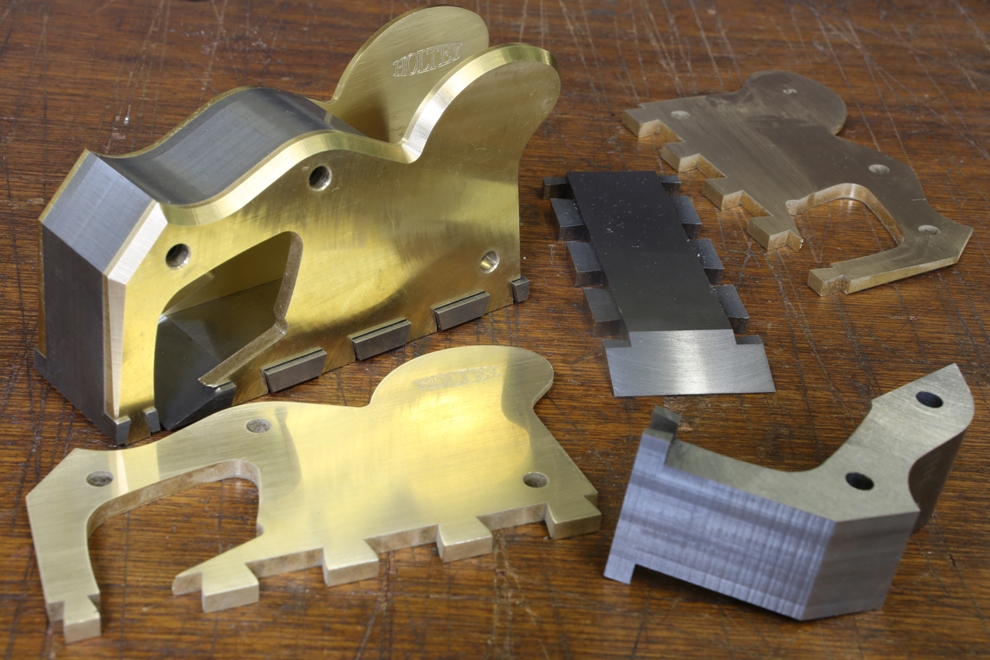

This picture shows some idea of all the work that goes into this plane. Unless you have done it yourself you can never imagine the effort and thought that goes into making this Chariot. This plane is made to a standard light years beyond its original counterpart made by Norris.

During the working of this A28 plane I have been neglecting this blog but now I am ready to update which I will do over the next few weeks.

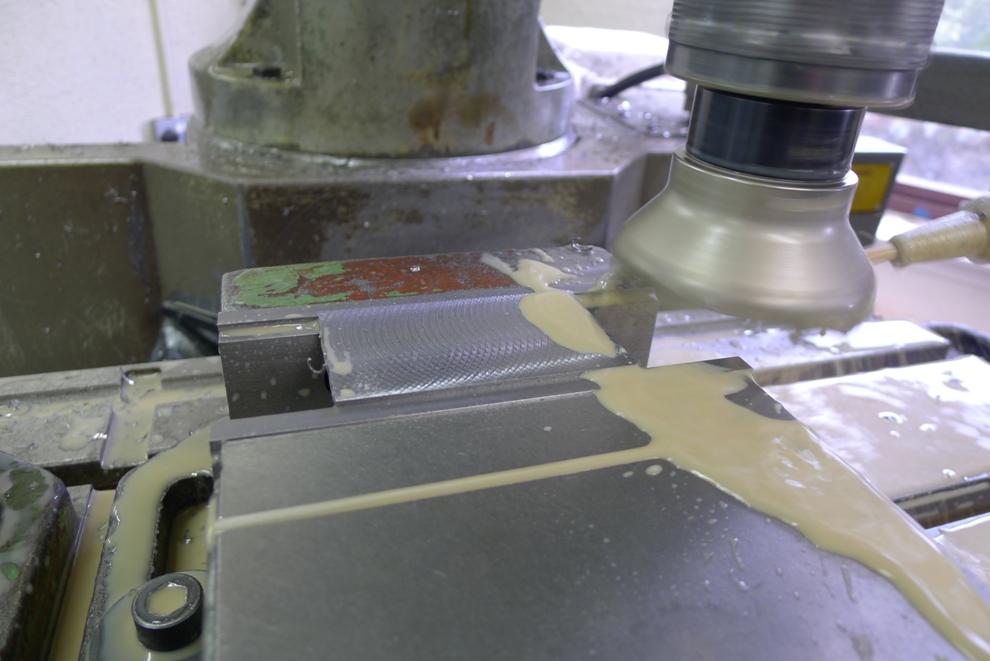

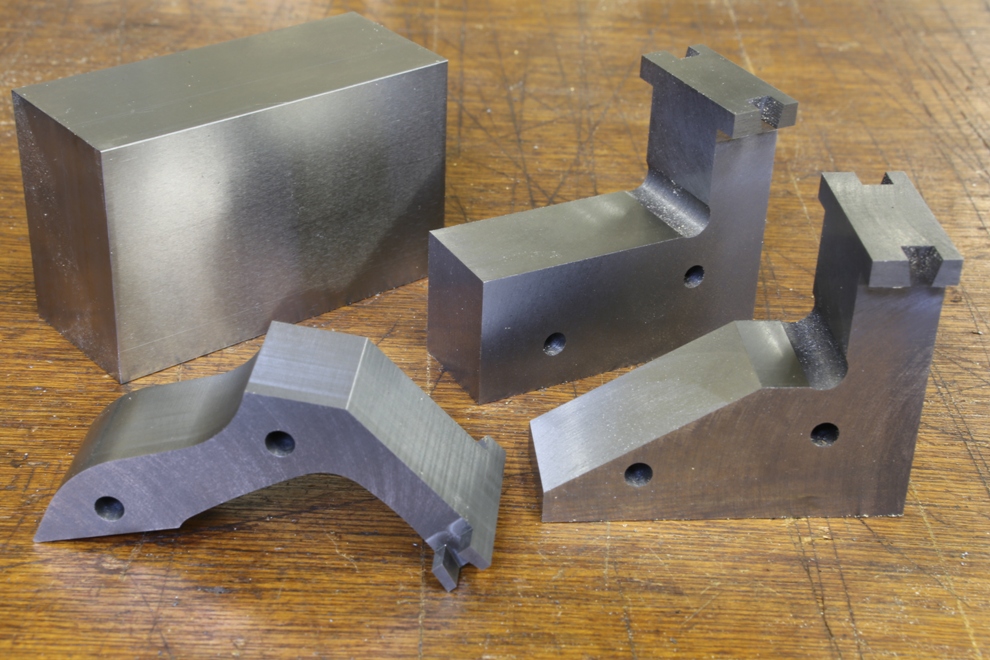

All the sections I use are cut out of stock material and brought down to size, by sawing and milling.

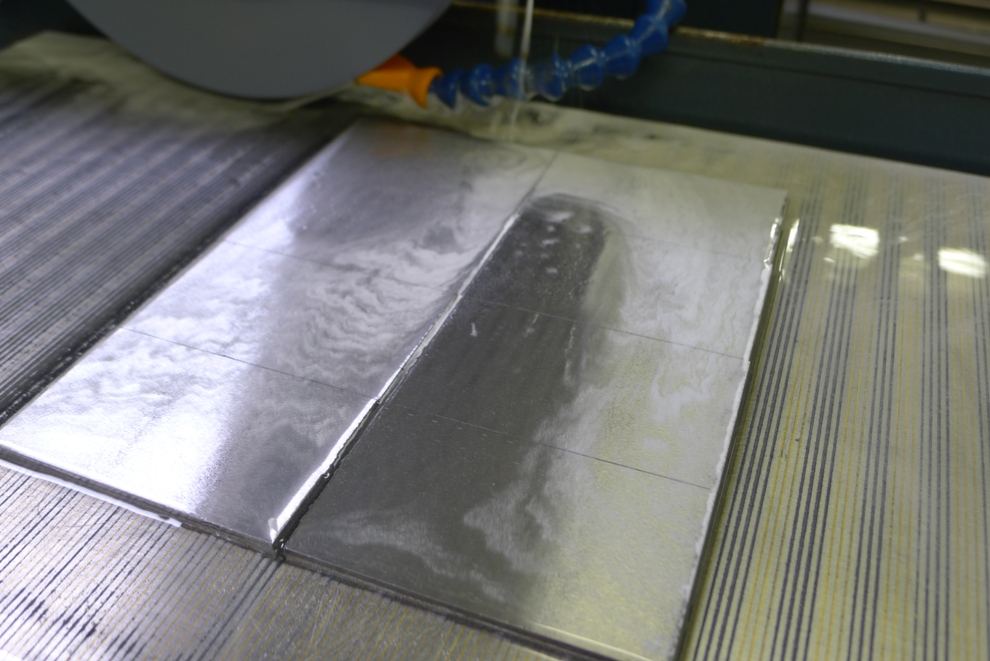

As most of my working and setting out depends on a high degree of precision (which has never existed before) surface grinding in the early stages allows me to achieve my goals.

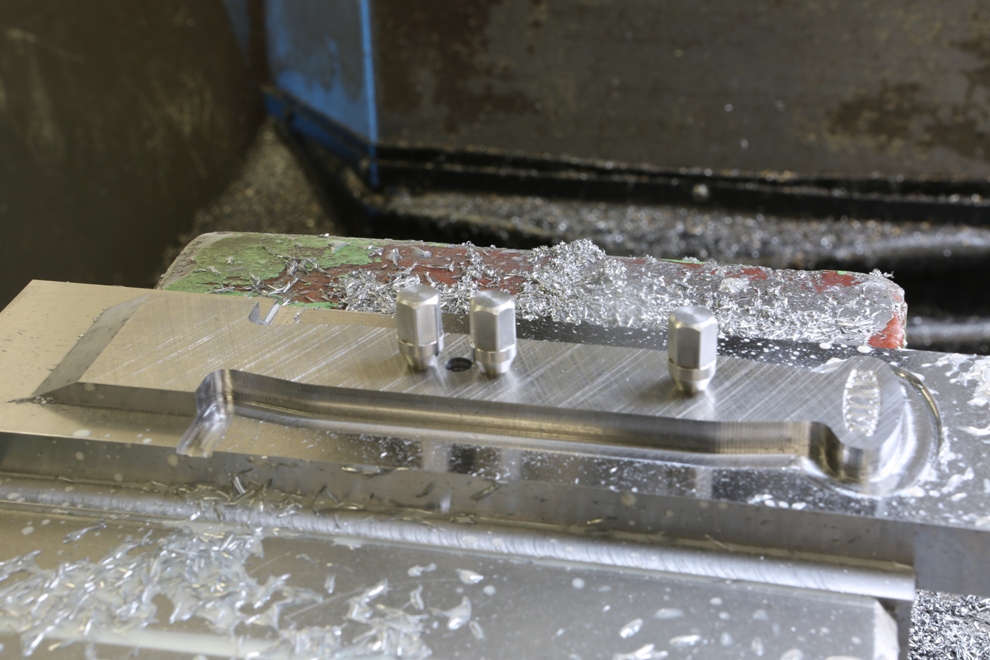

This picture shows the edges being ground. This is also important to have a true pinch dimension. I need this for the dovetailing.

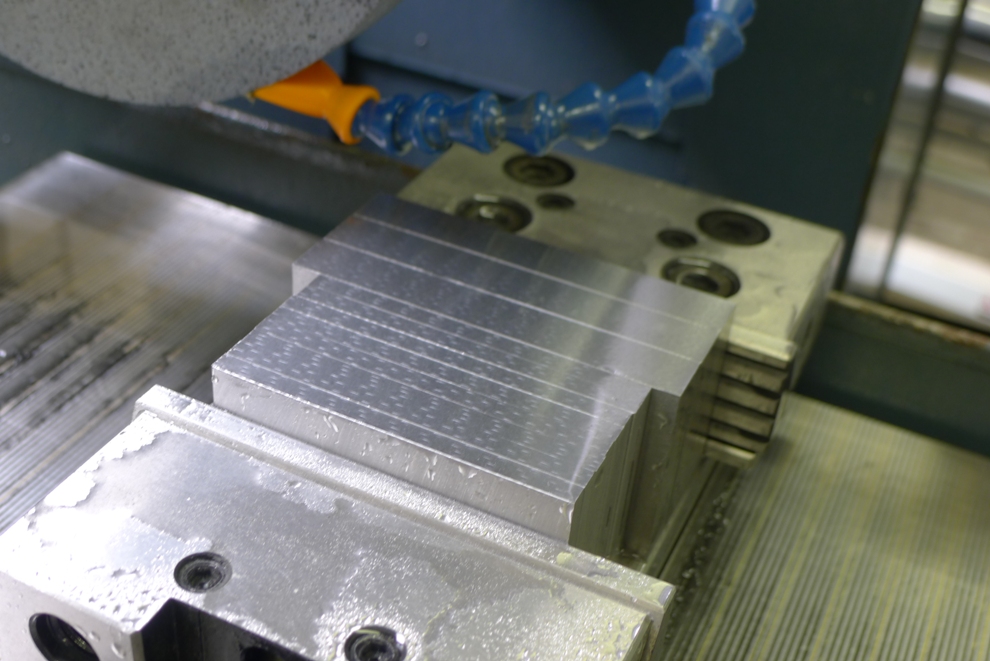

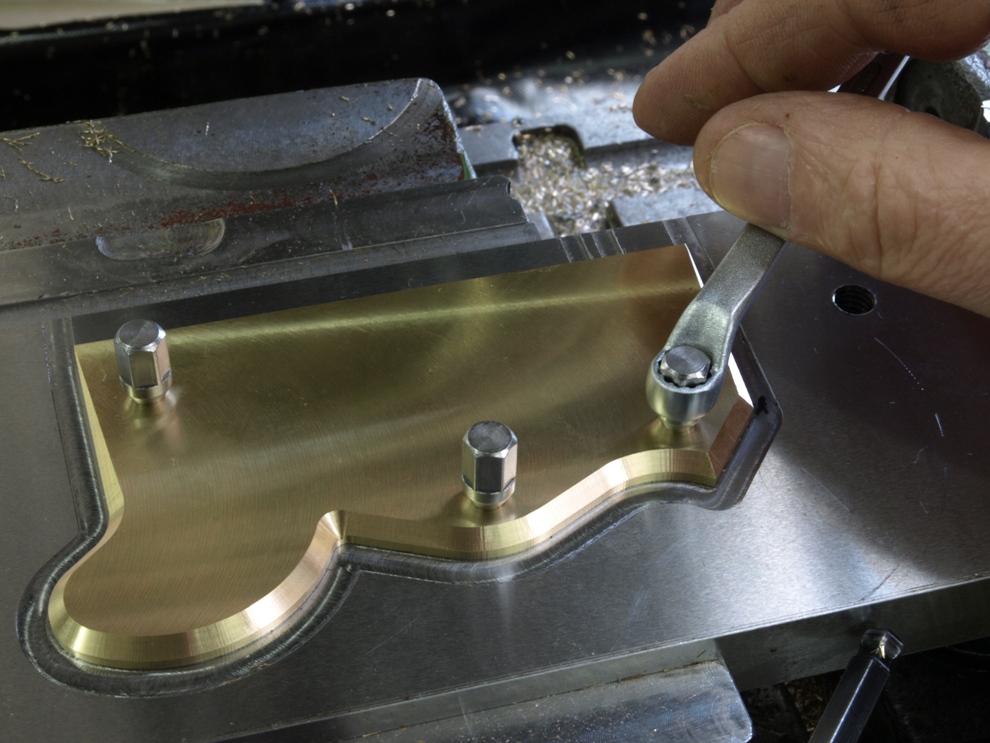

Jigs and work holding fixtures are also all made to precision. After much preparation work to the brass, similar to the steel work as described. Then rivet positions are drilled and I am able to screw these sides with purpose made bolts to the fixture for profiling and chamfering.

After routing out the profile then the chamfering is completed whilst the sides are still jigged.

Just overall set up pictures.

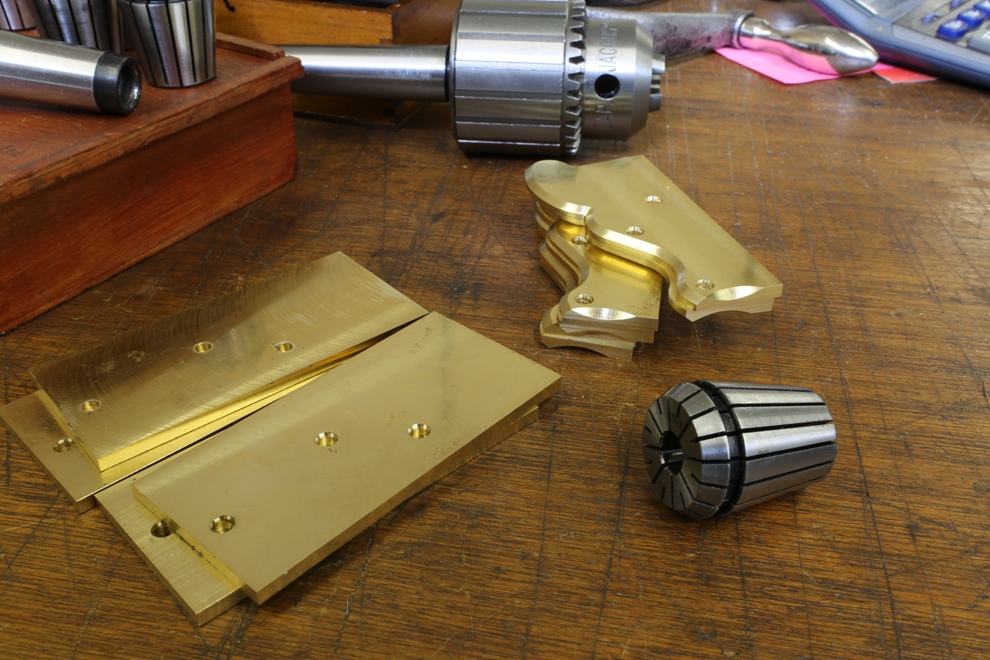

Here are the some sides already milled and some pre-prepared waiting for profiling.

This Chariot is the last item in the series of low angle planes I have been making recently. I have only made a few of these planes and that was a long time ago in my early days of plane making. Then my side profiles were cut by hand and I made up a template which I would scribe round. Now that I CNC these the machine can’t see my template so I have had to re-draw it showing co-ordinates to write a programme from.

This line drawing by today’s standards might look a bit primitive but I have never had the leisure to learn to use a CAD. With a drawing showing contours I can write this in to my control unit. Drawing contours is more instinct than anything and I just know when it is right however long it takes (I would be ashamed to tell you how long these ones took).

Blades back from heat treatment. They have been vacuum hardened and triple tempered, followed by a two hour nitrogen soak. Note that there is no colouration to the blades, which means there were perfect conditions with no leakage.

Now they ‘just’ need polishing and surface grinding.

Blades for the Bullnose plane

The blade is secured by its adjusting holes etc, in a purpose made holding block, for profile milling.

The milling is coming to an end of the first cut.

The finishing cut.

Profiling complete, with just the side bevels to be done. This is a quick summary of some of the blade work.

A picture of the main components ready for assembly. It has been a long time getting here. It is just like climbing a mountain – you keep seeing false summits.

Back working on the Bullnose after so much downtime with the grinding machine maintenance:

Pictures 1 – 4

This is the cast iron infill for the Bullnose. As you can see this is a complex shape so I will let the pictures speak for themselves. As with most things I design and make I go places that have never been visited, making these planes very unique.

This shows the pin side of the dovetails being milled.

Rebating the tops of the dovetail area, which provides a light stop and gives the dovetails a better form. Again this system is unique to my planes.

One of the problems of making precision planes is needing your own tool room. This means that on occasions maintenance is necessary.

A simple task like cleaning my coolant tank got so complicated that two weeks went passed before I could get the grinding machine back in service again.

My schedule is now running late and I am looking forward to getting back to working on planes again.

This is one of only six A27 Bullnose planes I made many years ago. This was made by casting as were the original Norris. There were one or two downsides to this method of production so for some time I have been contemplating making a fabricated version using traditional dovetails. Now that time has arrived. It will be a limited edition, and as you will have realised I am moving away from traditional infill planes so unlikely that I will make these again. This is the second plane in the set of three low angle planes I have been making for some of my customers – A27, A28 and A31.

A quick line drawing of the proposed plane. This is being made with naval brass sides (CZ112) and malleable cast iron for the bottoms, fore-end and bridge sections. I will be using a traditional wooden wedge and the adjuster housing is also rosewood. To my knowledge a Bullnose plane has not been made since Norris’s time in the 1920s – when it cost 23/- (shillings). I shall have to charge a little more. I have also moved the goalposts in regards to quality and precision.

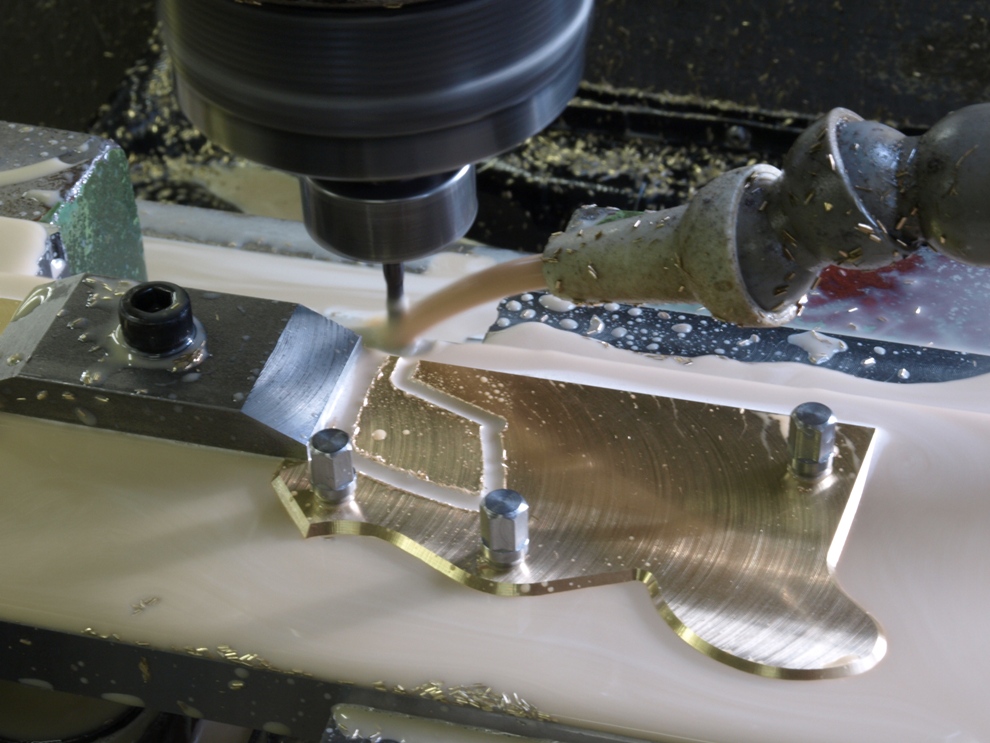

The sides being routed on the CNC mill. All the precision work holding tools and jigs I made myself before starting this. Every plane I make has individual jigs and work holding which are surface ground to a high precision. My tool room has been built up over many years and is, I believe, the only one of its kind. You will not find this standard of precision anywhere else.

The riveting holes, include a 60 degree chamfer, which provides the jig fixing and positive location.

The mouth being cut out last as a separate job as it needs an additional clamping to support the front end – which can be seen to the left hand side of the picture.

Here is the finished side except for the dovetailing. It includes its mirror partner completing the pair.

As usual to be continued when I next have an opportunity.

Powered by WordPress