As I have mentioned before most of my entries will be piece meal and out of sequence. On this occasion I have managed to take some pictures whilst making chip breakers. Apologies for missing the bending and forming of the front edge of the chip breaker but I forgot to take the pictures.

These chip breakers are standard on all my smoothing planes with 2 ¼” blades. They are made from gauge plate.

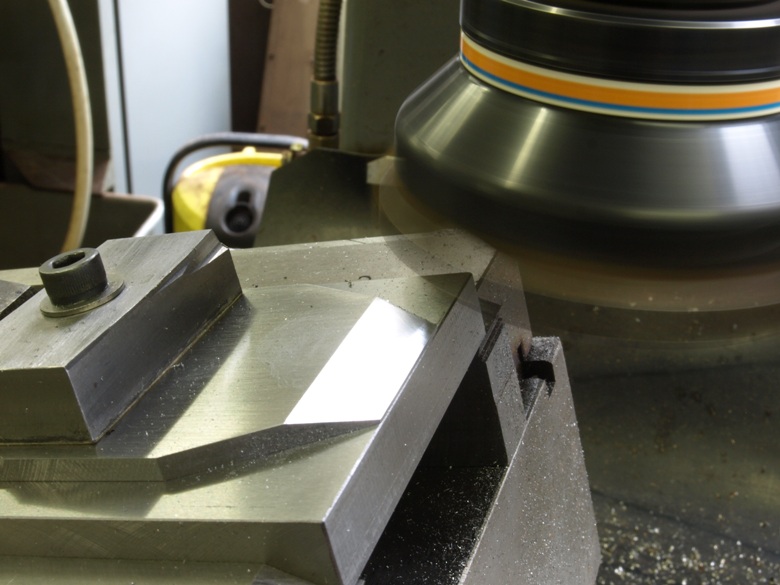

Milling the faceted end of the chip breaker with a rough cutter.

After cutting out the facet I go round with a finishing cutter for finishing and size

I have already formed the basic shape, and this is applying the rounding to the front edge.

After the rounding the hand polishing is done to the top side and the round.

Bevelling the facet. It is worth noting that it is important to get the sequence right to maintain that sharp, crisp finish. After this work is done the edges will be ground and polished all round cosmetics.

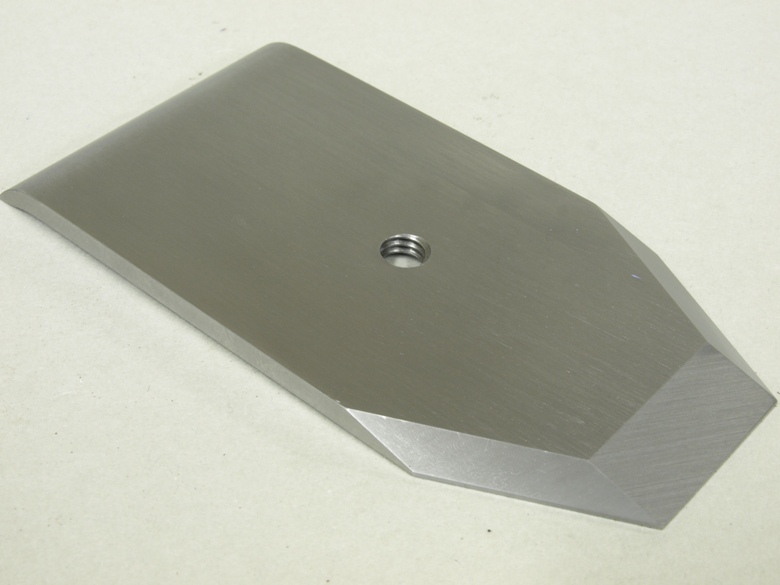

The finished chip breaker. Sometimes I might polish the bevel faces but of late I have preferred to leave a good milling texture. This gives a much sharper appearance.

Hey Karl,

Long time no see/read…

Very nice pics of a seldom discussed component,obviously for the older infill designs???

I’m getting a wee mill for my birthday in a couple of weeks,you might have some competition in a decade or two…

Karen says hi to you,the Missus & your hairy babies…

Black

Comment by Adrian Baird Ba Than — June 29, 2010 @ 9:24 pm

Karl,

I have been going cold turkey for a long time. You are my heroin and this fix is as good as the first !!! Welcome back my dear friend.

Archie.

Comment by Archie — June 30, 2010 @ 6:43 pm

Karl,

Its been a long time between drinks – glad to see some more photos of your work posted. Yet again a beautiful display of excellent workmanship.

I have a question – what is gauge plate and how does it differ from mild steel?

Thanks

R

Comment by Richard S — July 2, 2010 @ 9:45 pm

The finished chip breaker by itself is beautiful, even without the rest of the plane! Thanks for sharing your work with those of us who can’t currently afford (or justify to their spouses the cost of) your planes.

Comment by Asher — July 16, 2010 @ 6:12 pm

Greetings,

I was just sitting here perusing your website and dribbling into my laptop.

As I was admiring the crisp sharp and technically flawless chipbreaker I thought to myself “why do they not bear the Holtey stamp”

So Karl, Why ?

Archie.

Comment by Archie — August 20, 2010 @ 6:15 pm

Hi Black

Unfortunately I seem to get a steady stream of visitors which interupts my work Time melts away and I have no idea of whether it is winter or summer – especially as looking out the window gives me no clue, I think it is winter.

Time melts away and I have no idea of whether it is winter or summer – especially as looking out the window gives me no clue, I think it is winter.

Presumably you now have your mill so lets have some pictures of it and progress pictures on the plane that you have started.

The babies are doing well. In fact Anlon is turning into a little star and took the Best In Breed at the Leeds Championship show. Hope you little boy has recovered from the run in.

Regards to the long suffering Karen

k

Comment by admin — August 22, 2010 @ 10:11 am

Hi Archie

Another long absence, sorry. Promise to buck up

k

Comment by admin — August 22, 2010 @ 10:16 am

Hi Richard

Apologies again and any quality malt will do.

Without diving to my reference books and impressing everyone with a detailed answer about the difference between gauge plate and mild steel. The mild steel is a very workable material commonly used in almost everything. Gauge plate (01) has a higher carbon content which is generally favoured by tool makers as it is easily hardened through heat treatment. It is usually sold in round, square and rectangular sections and comes pre-ground. I know some people use gauge plate to make planes but I find it unsuitable because there can be a tendency for brittleness as it is not very malleable. It is tempting for a lot of amateurs as it is in a ground condition. In its hardened state many people used it for blades until I pioneered A2.

Thank you for your nice words.

k

Comment by admin — August 22, 2010 @ 10:29 am

Hi Asher

Thank you for your compliments. I find that many of my customers are not rich but make it a once in a life time investment. Although I am finding that many of my customers now own more than one of my planes.

In the meantime I hope you find the blog interesting. I do intend to step up my activity here.

k

Comment by admin — August 22, 2010 @ 10:32 am

Hi Archie

I think putting my stamp everywhere can look too boastful. I take more pride in keeping a low profile, after all it should be quality first then name. Sometimes I even stamp my name on the underside of the blade.

k

Comment by admin — August 22, 2010 @ 10:39 am