After the completion of the No 982 smoothing planes it was not long before I was pressed into making a larger version in the form of a panel plane. Because of the enormity of work on this plane I have decided to make only 8 for this batch.

For the benefit of those who have bought this plane I would like to blog the making. Hopefully it will show up some areas I did not cover on the smoothing plane blog.

You will notice that I do change my techniques from time to time.

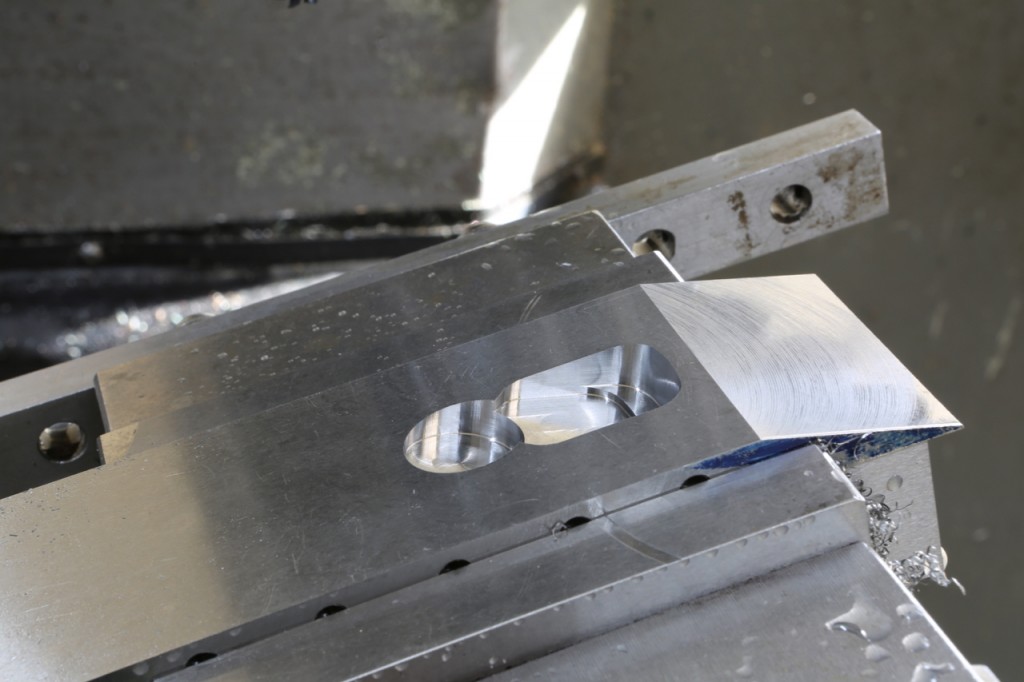

I will start this blog by documenting the work on the lever cap. I would like to emphasise the work that goes into this one component. Though I have used castings in the past for my lever caps I feel more in control by making them from a solid bar and I produce a far better product. I now understand why some of the Rolls Royce cameras bodies are made from solid billets.

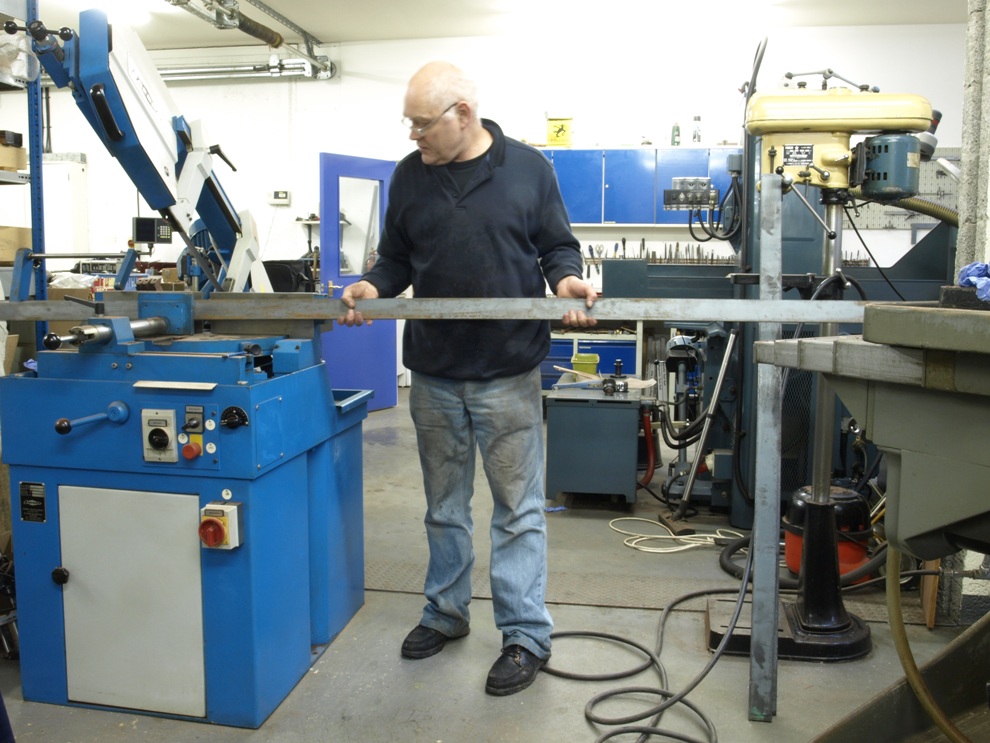

Starting with a bar of naval brass I go round and machine all the sides true, just like you would with a piece of wood.

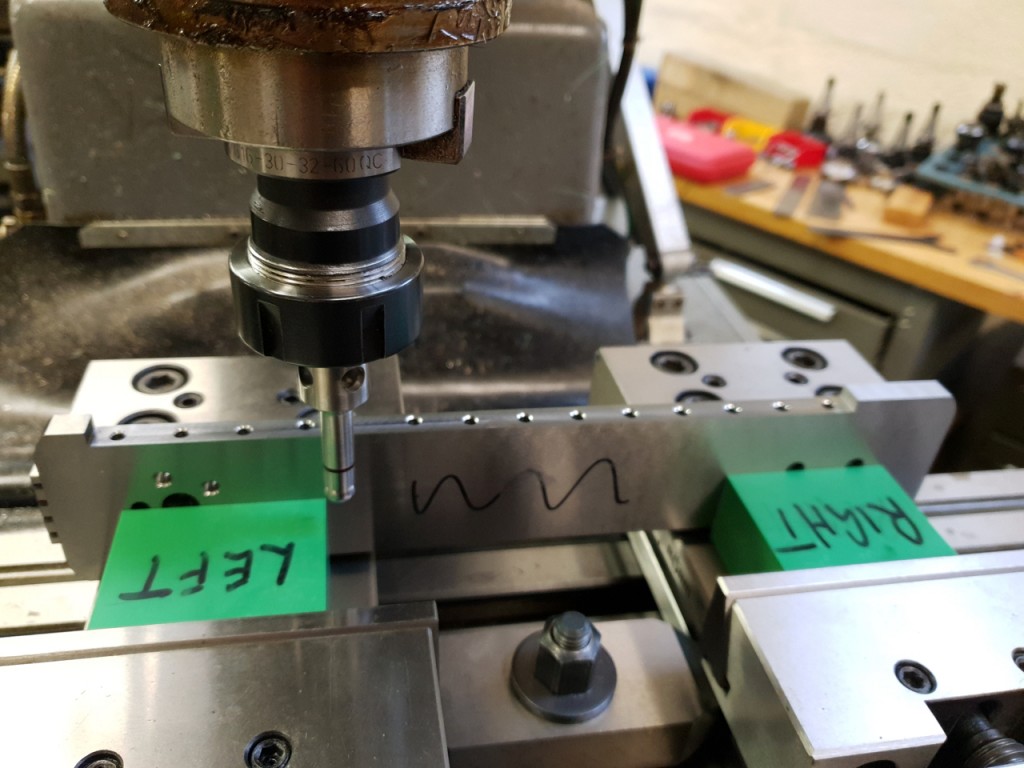

If this was a piece of wood the next stage would be to machine a form i.e. either with a spindle or a router. In the case of metals I have to concentrate more on work holding so this picture shows me setting up three vices in a line. The bars I am working are 18 inches long and cut 8 lever caps each.

(more…)