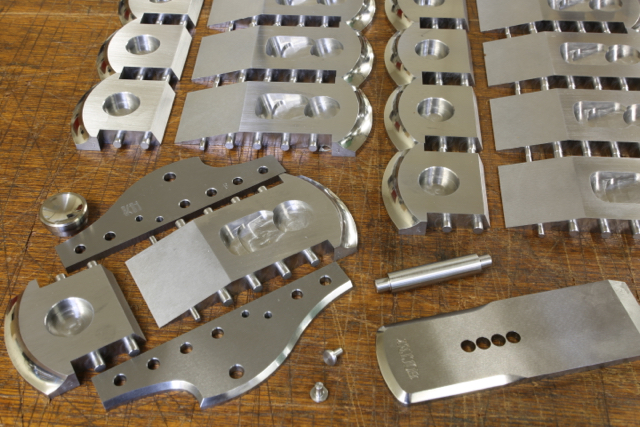

All the chassis work done on my No 983. A lot of f…… work done

November 21, 2019

October 10, 2017

July 6, 2017

Window to my Workshop 115

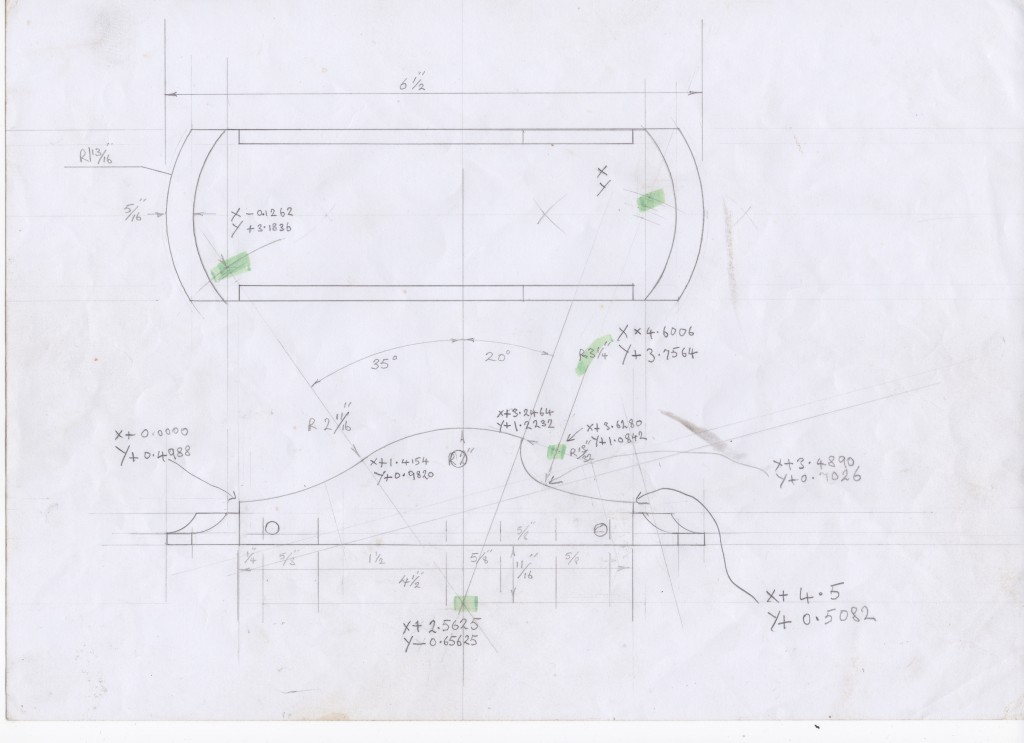

In conversations over the years I have always been praised for my (primitive) drawings as CAD is the way now. (See the dinsaour card on my Facebook page – thank you David) I have never had to time to learn CAD. The hardest thing was to learn an early Heidenhain control unit for my mill. I am just starting a new batch (yes, I know I am supposed to be retiring ![]() ) of these No 983 planes, mainly because I sold the last one which was mine, I am going to use this opportunity to explain some of the workings in more depth. Maybe because I am getting older the work seems to expand but I have never allowed economic restraints to get in the way.

) of these No 983 planes, mainly because I sold the last one which was mine, I am going to use this opportunity to explain some of the workings in more depth. Maybe because I am getting older the work seems to expand but I have never allowed economic restraints to get in the way.

Going back through some of my drawings, which are very untidy, I decided to post some up. Starting with this side layout of the No 983 – warts and all. This is how I work and then I have to convert it into a suitable dialogue for my Heidenhain. Luckily I am the only person who has to understand this.

December 2, 2013

Window to my Workshop 75

November 11, 2013

Window to my workshop 74

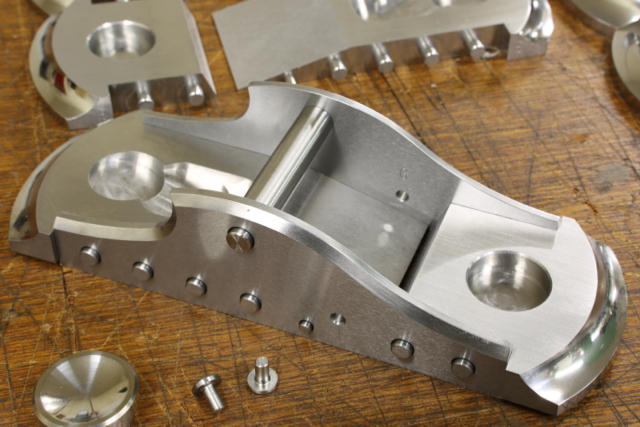

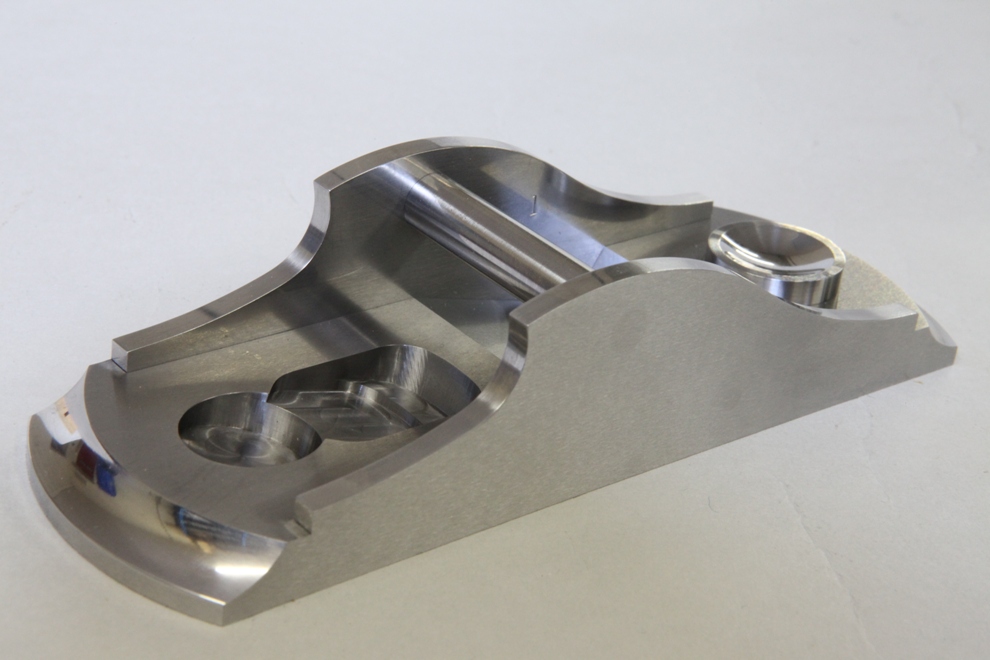

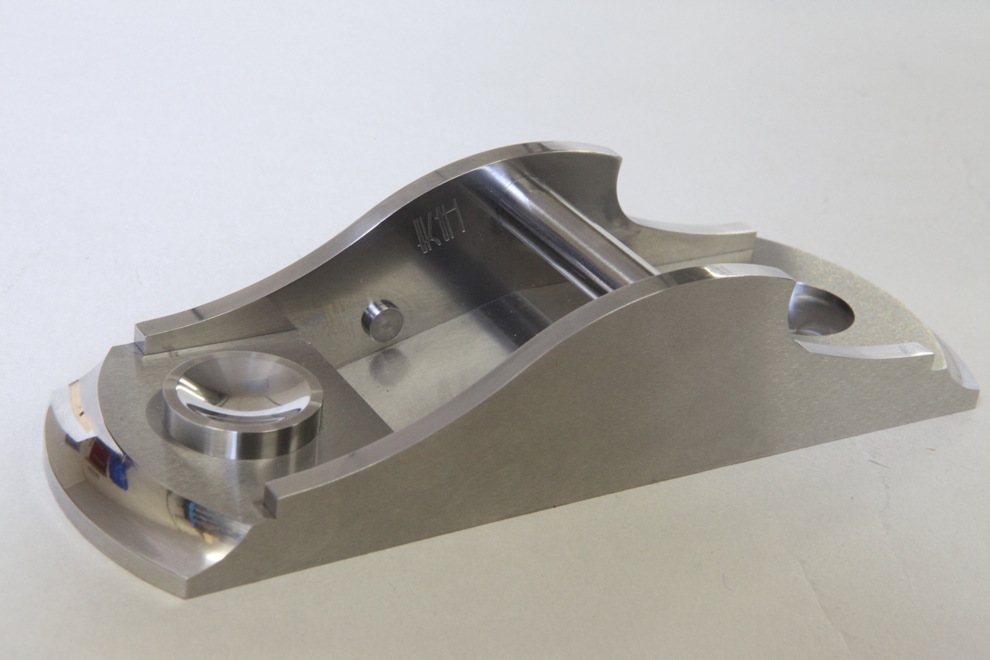

As this lever cap has taken a very long time to make I thought this picture, of it not even half way completed, tells some of the story. The milling, grinding and polishing has to done in sequence to achieve the finish I require. It will be a complex shape when completed.

October 25, 2013

Window to my workshop 73

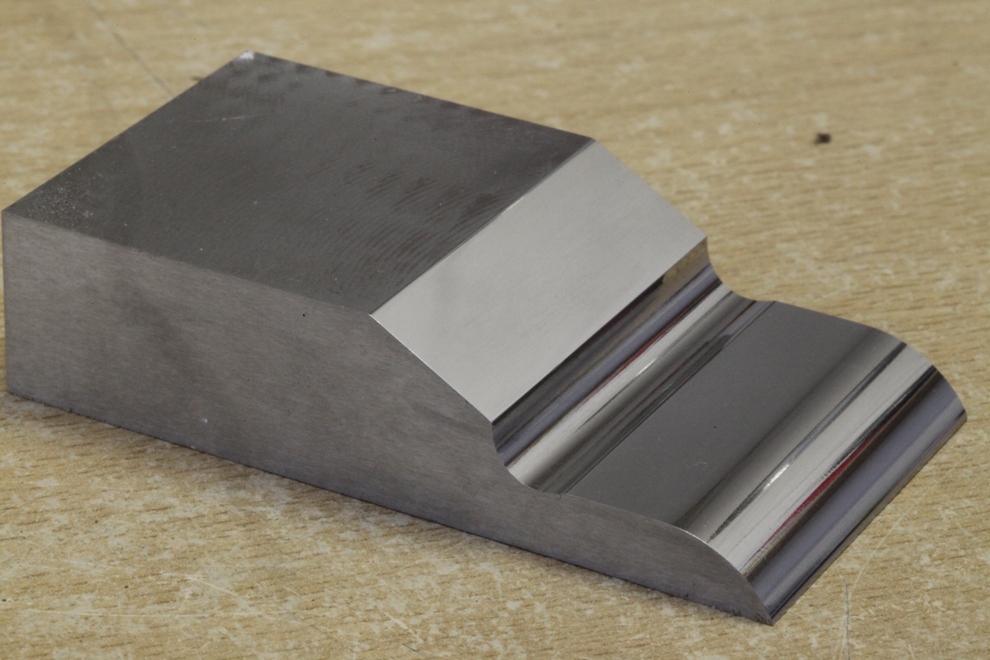

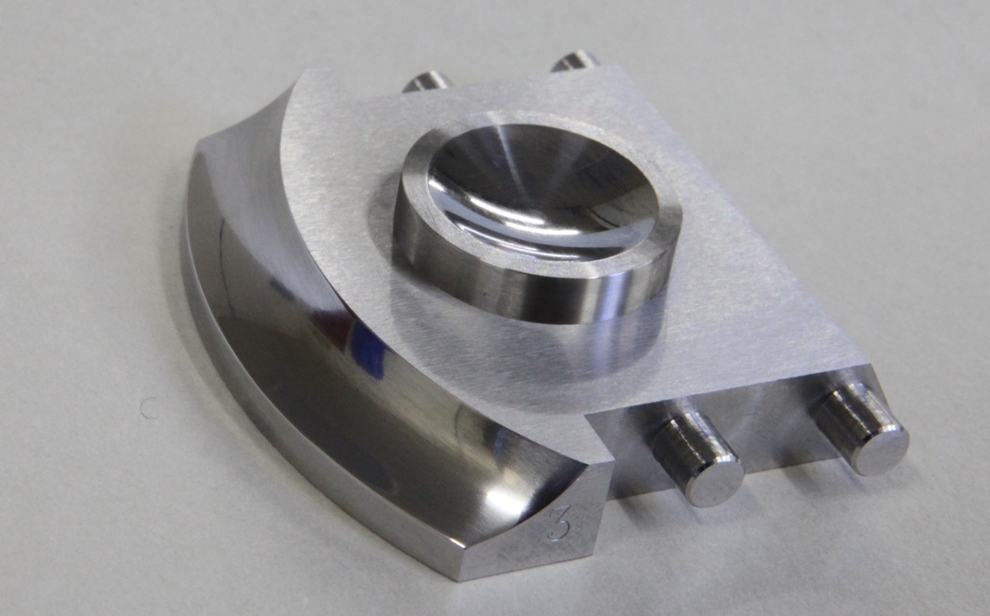

After several weeks of design, trial and tribulations, the thumb wheel in stainless steel is finally complete. New designs and ideas are always time consuming.

This picture shows the thumb wheel inverted and assembled with the floating spherical washer (the washer does not appear to be central on the photo as it is floating). This works with the matching spherical depression in the underside of the thumb wheel like a ball and socket; evenly spreading the load over its area, helping to eliminate any lateral movement on the blade as you tighten down on it. It also helps to evenly distribute the pressure throughout the blade bed reducing body distortion.

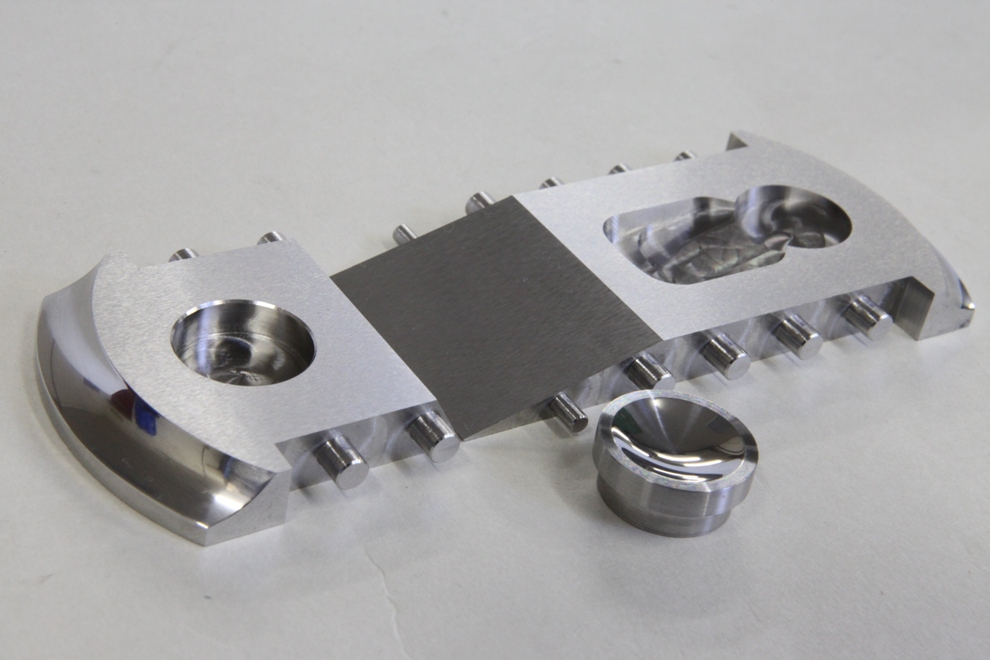

These are the three components making up the thumb wheel. I have changed the grip arrangement on the thumb wheel and screws. I dislike the fact that a lot of knurls fill up with dirt. Aesthetically I find this method, though labour intensive, is more pleasing and feels comfortable on the thumb/fingers.

I would like to emphasise that, as always, all my components are hand made, in house.

No 983 Commentary

I want to go back and take the time to explain the development and design of the No 983. I will be updating the website with this during next week. When I made this plane I only did a limited number which sold out quickly so I had to make another batch. It is very satisfying to complete a design but I am not going there again as the work is far too much. I won’t make the mistake of selling the last one (mine!) again, but I do have two left for sale.