No 10 smoother/mitre

A very patient customer asked me to make a small mitre plane. He wanted a 11/4” wide blade to be bedded at 25 deg and bevel up with a short body. No adjuster was required.

I would classify this plane as a smoother/mitre. The small mitre plane has always seemed to be surprisingly scarce for its usefulness. Having got my simple sketch approved the first batch is now well on the way (the sketch can be seen on the website here http://www.holteyplanes.com/).

It is a combined stainless steel bottom with naval brass dovetailed sides and brass lever cap and thumb screw. The blade is in my A2 original specification and has a top sneck. The length of the plane is 43/4“.

Despite its apparent austerity there will be no lacking in specification and quality. The designation will be No.10. Delivery will be end of November 2011.

What better place to start than the blades. Here are the A2 blanks being drilled and shaped. These are now away being heat treated (the only work to be done out of house).

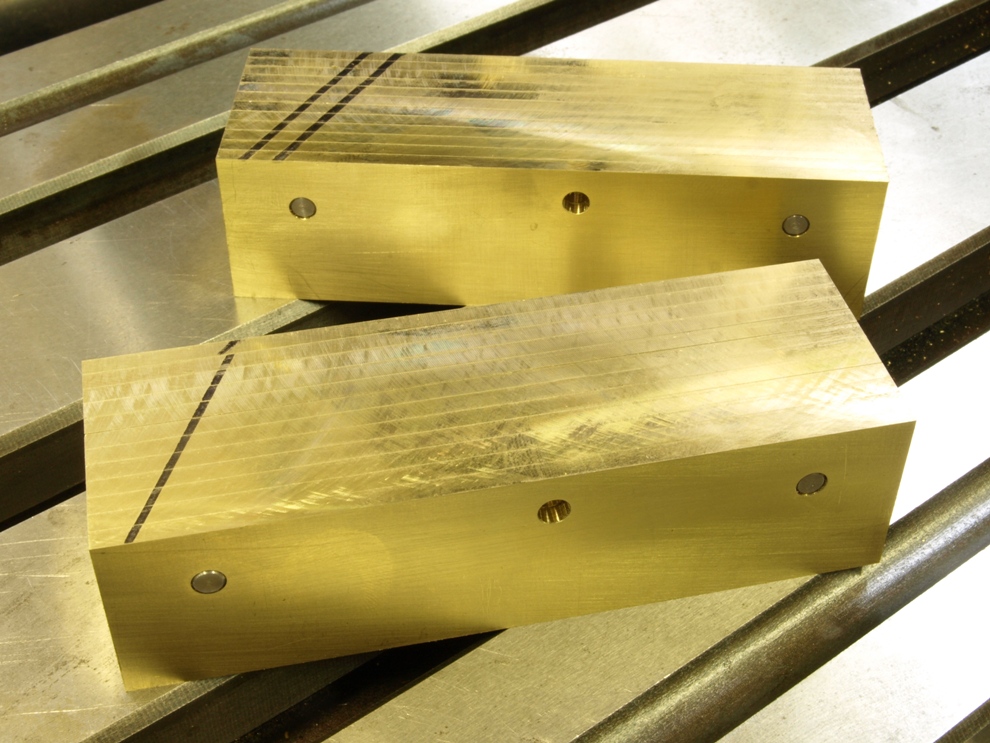

Brass sides have been cut from sheet and trued up into rectangular blanks.

Then CNC drilled for indexing purposes. I am then able to press silver steel pins through the holes holding them in sets of 12 ready for dovetailing.

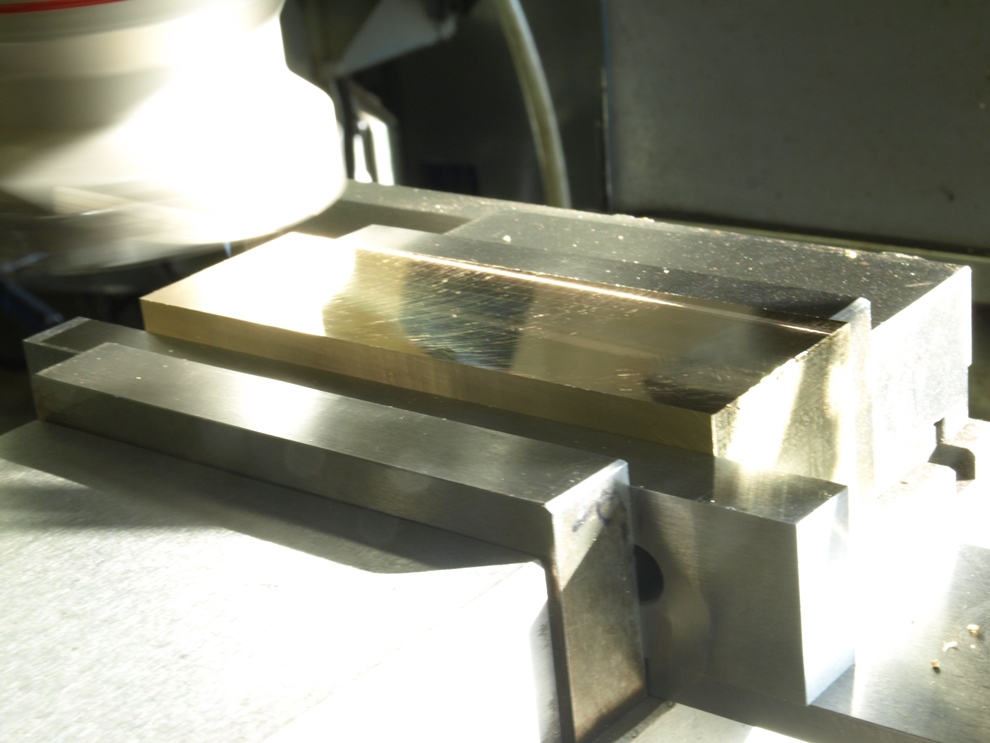

Work holding set up with datums for the first batch of 12.

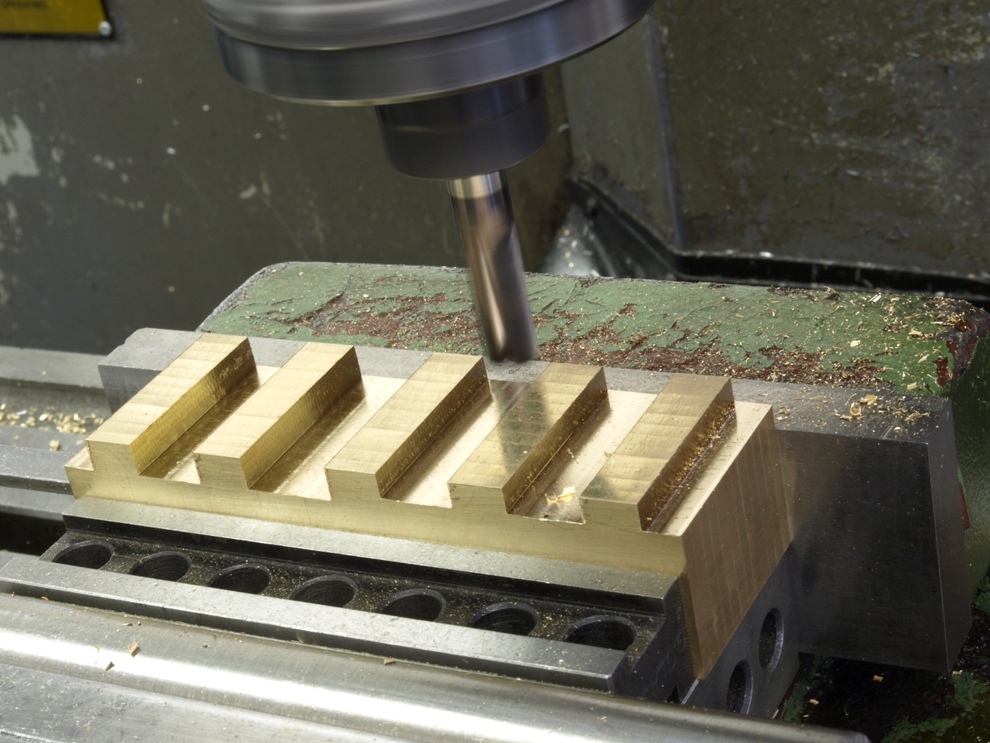

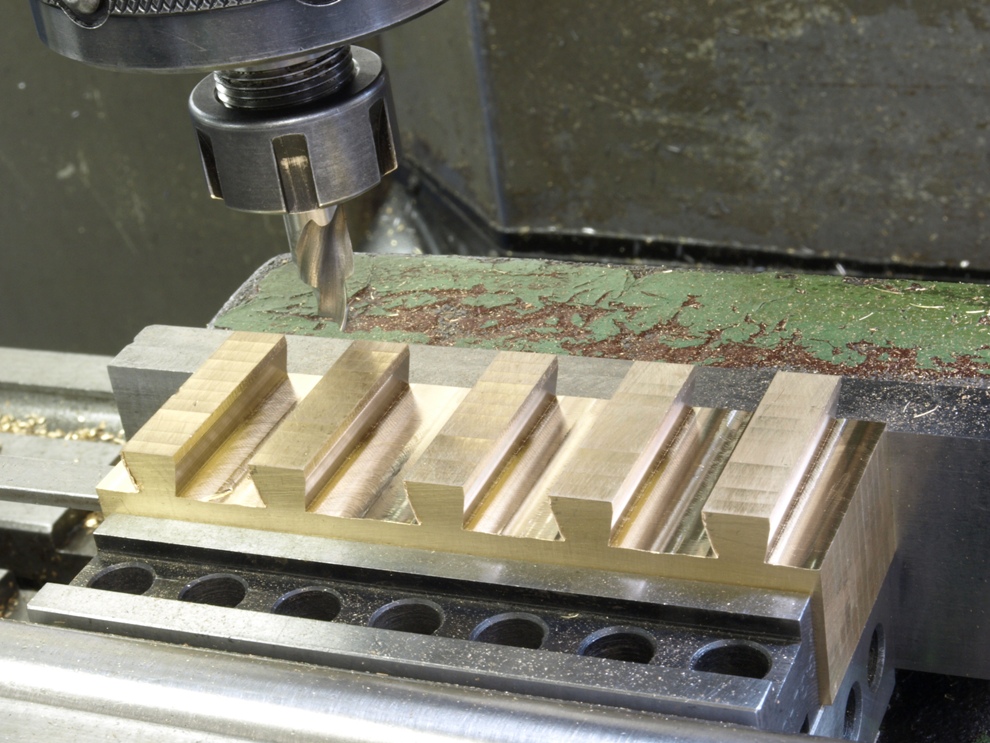

For clarity I have cleaned up the mess for these pictures which show the milling and forming of the dovetails.

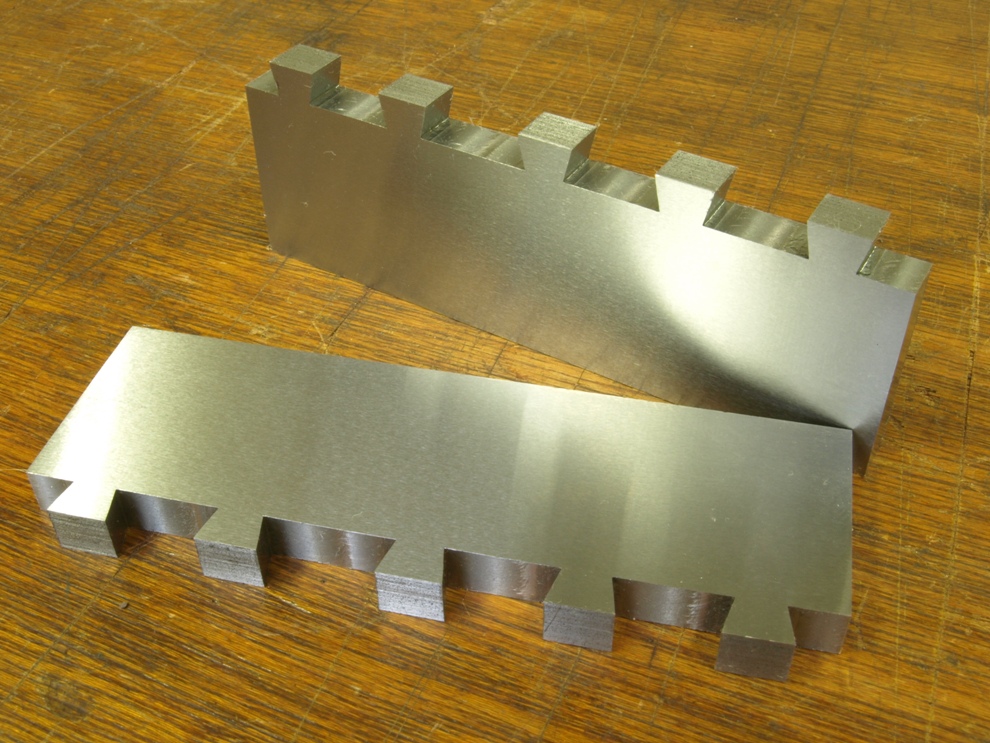

Whilst the dovetailing set up is in place I need to remember to make my clamping plates. The use of these plates has been demonstrated before in my A6 blog, but you will see their use for the No 10 later. As you can see these plates are surface ground as in most of my tooling.

Excellent as always Karl. Awaiting more developments. Could you give me an idea of where on the website the sketch of the plane is, I can’t seem to find it.

Scott

Comment by Scott MacLEOD — October 17, 2011 @ 4:41 pm

Found the drawing, thanks.

Scott

Comment by Scott MacLEOD — October 17, 2011 @ 4:50 pm

Hey Karl,

I really like these small planes, look forward to seeing the finished item. What infill is the client going for?

By the way, managed to score a wee digital kiln for heat treating, just need to find someone to give me some liquid nitrogen for the cryo…

Hi to Claire,

Black

Comment by Black — October 17, 2011 @ 10:44 pm

Hi Scott

Glad you found the drawing, I have now put a link.

k

Comment by admin — October 18, 2011 @ 10:32 am

Hi Black

I am going to use the three most popular timbers – boxwood, ebony and rosewood.

Do you have enough 50p for your new kiln? As you know I leave all my heat treating to the specialists. The only thing that is outsourced.

k

Comment by admin — October 19, 2011 @ 5:57 pm

Hey,

I’m not sure what having enough 50p means but the kiln chamber is pretty small, only 200mm by 200mm by 150mm & as it’s less than 2 kilowatts a single heat treat only costs about 25p as it gets to 788 degrees C in under an hour (plus soak time,depending on metal thickness, 7-15 minutes)

It might also be possible to make my own Damascus steel as well as large sheets of Mokume Gane, I’m in the process of building a compact hydraulic press to be used in conjunction with the kiln….

Excited?

You betcha…

B

Comment by Black — October 20, 2011 @ 12:02 am

Hi Black

In days of old people had electricity meters that were coin operated and I thought your kiln would be eating up electricity – I stand corrected. I thought you wanted to use a kiln to harden steel. The Mokume Gane is lovely. I have come across it before in my search for decorative metals but having another look I am even more impressed with it.

I am certainly interested to know anyone who can provide me with decorative metals for small planes. I find the Damascus is getting too common, and the downside is that it needs to be chemically treated for colour which means it can wear off.

You like an easy life …..

k

Comment by admin — October 21, 2011 @ 9:23 am

Hi Karl,

Aaah, I had one of those meters when I was wee…

Yes, the kiln is for hardening steel blades, as well as making the decorative metals. I can also use it for lost wax casting, glass work & even ceramic firing albeit within the limitations of its size. I’ve already used it to treat 4 straight razors & 1 Ray Mears type bushcraft knife.

The Damascus is becoming quite common, I agree, but it can be quite deeply etched with ferric chloride so you get rather definite separation between the layers. I think the odd lever cap or knurled knob could still be quite striking.

B

Comment by Black — October 21, 2011 @ 1:08 pm