A6 Part 2

*************

All of the woodworking has its edges squared up on the milling machine as I have a bit more confidence in this machine than I do a planer.

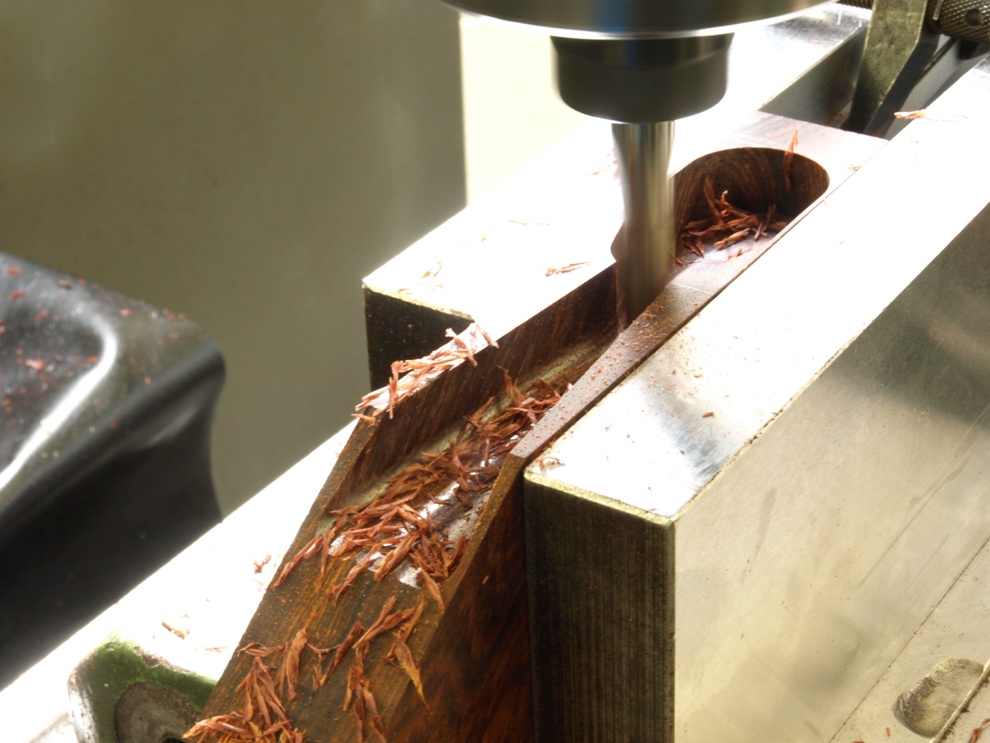

A pair of infill sides being drilled for riveting spacers. At this stage all edges are trued up

This is the infill side with the spacers pressed through the handle testing for fit. The two sides have yet to be separated.

After separating and shaping, the sides are rebated as a pair to create an overstuffed infill.

Drilling the adjuster plate. This is one of six components to make up an adjuster.

After drilling the plates are screwed to the work holding plate for profiling.

Drilling for the handle spine.

Counterbore for the handle spine.

Handles ready for their brass spines. Yes, there are some spares but they can be used for the A13 by drilling an extra set of holes.

With the spines cemented in, the heads are flushed off.

Adjuster recessing is not just easier on the CNC mill but it is also much neater.

The handles are now ready for hand shaping.

What type of cutter do you use when you are planing wood on the mill. A standard metal at a higher speed, or ???

Thanks again

Scott

Comment by Scott — August 2, 2011 @ 7:27 pm

Hi Scott

Unlike most metals wood requires a higher surface speed for cutting. The engineers milling machine doesn’t really have the spindle speeds for this. The type of cutter is important and with cutters and end mills I always use tungsten carbide tools which come in various coatings and without coating. The face cutting head which is in the blog has 5 cutting tips, these come in a very wide range of types. The ones I use for wood can be of several types but need a much keener edge than that used for metal materials. I find that the tips recommended for cast iron and bronze alloys have a good edge on them which works quite well. For end mill cutters the finer grade (more expensive) carbide cutters also cut nicely in wood. Wood will wear a cutting edge much faster than metal.

k

Comment by admin — August 3, 2011 @ 9:28 am

The handle blanks themselves are worth the price of admission; can’t wait to see the plane itself come together!

Comment by Torch02 — August 8, 2011 @ 3:56 pm

I am really not sure what you are making but that woodwork is beautiful and the craftsmenship is outstanding

Comment by mikejb1954 — August 16, 2011 @ 7:24 pm