I am hoping to get some feedback here, so please register if you haven’t already and comments will be appreciated.

Snecked Blades

In the course of my research I have found that the only planes that were made with snecked irons were shoulder planes, and the occasional thumb and chariot planes – these were side snecked as in my 11-s smoothing plane here (double sided sneck).

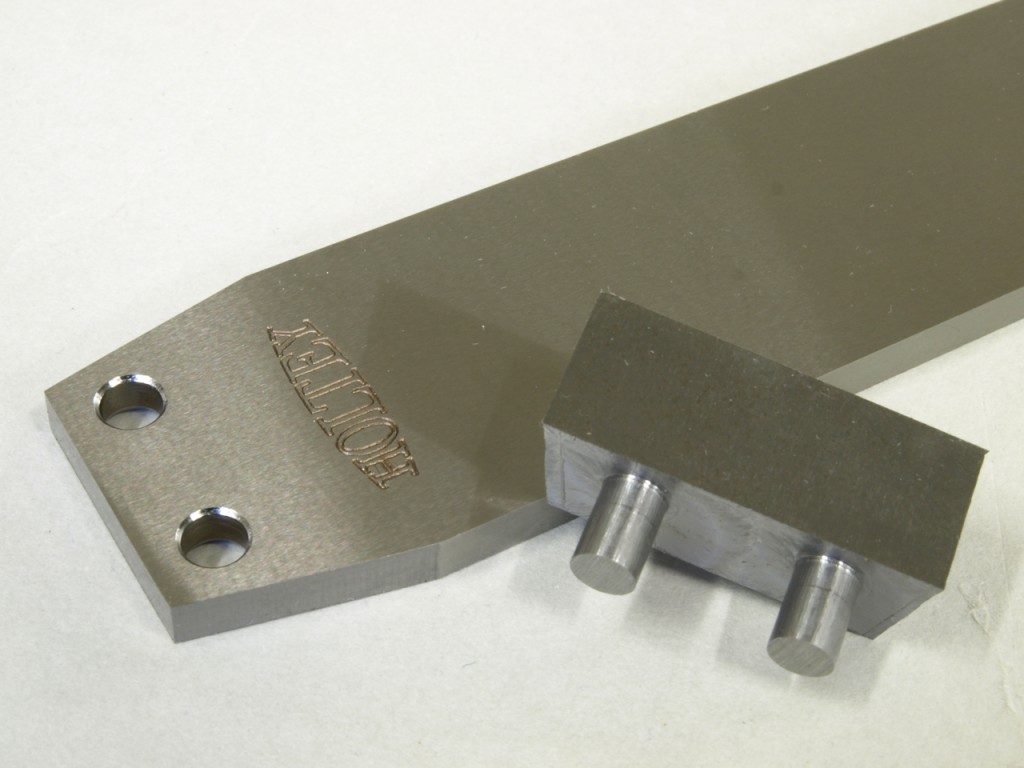

Mitre planes usually have top snecked irons, as in my No 10 shown here.

I can’t understand why smoothers and panel planes etc did not have snecked irons. Of course top snecking would require a longer blade as lever cap or wedge would restrict their use. A side sneck should still work on these planes.

Is it possible that the use of chip breakers had something to do with this?

I am working on a development plane at the moment and planning to make it a non-adjuster plane. I feel that having a snecked iron will make a considerable difference in setting up the blade. I am also wondering if users choose to use a non-adjuster plane because it is better or is it an elitist thing?

Interesting concept. I agree that it should work. Look forward to seeing what you come up with.

Comment by bobbb576 — December 4, 2018 @ 12:27 pm

I don’t know much about Plane history but it would seem to me that having a strike button on the rear of the plane would be far simpler than snecking the blade, particularly as you wouldn’t have to lengthen the blade. I learned early to ignore the side-to-side adjustment on my block plane and just use a pin hammer instead – It gives far better control over minute adjustments. It also crosses my mind that if my plane was a non-adjuster I wouldn’t have the adjuster backlash that is the bane of my life. So I think it would be unfair to characterise choosing a non-adjuster Plane as elitist (although no doubt some behave in a way that begs the characterisation)!

Comment by jimjam66 — December 12, 2018 @ 9:24 pm

Thanks for your comments which make sense. I have come to the conclusion that the earlier plane makers didn’t use sneck blades on smoothers and panel planes as they had chip breakers. I have decided to make a non-adjuster smoother which will reduce the cost considerably. I will be using a top sneck to the blade as this means a back stroke on the blade will be central – side snecking could mean dinking the handle. I will give a striking button some thought, good idea, but is more applicable for a handless plane.

Comment by admin — December 14, 2018 @ 11:37 am