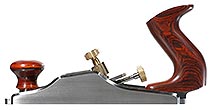

Holtey Classic Hand Planes

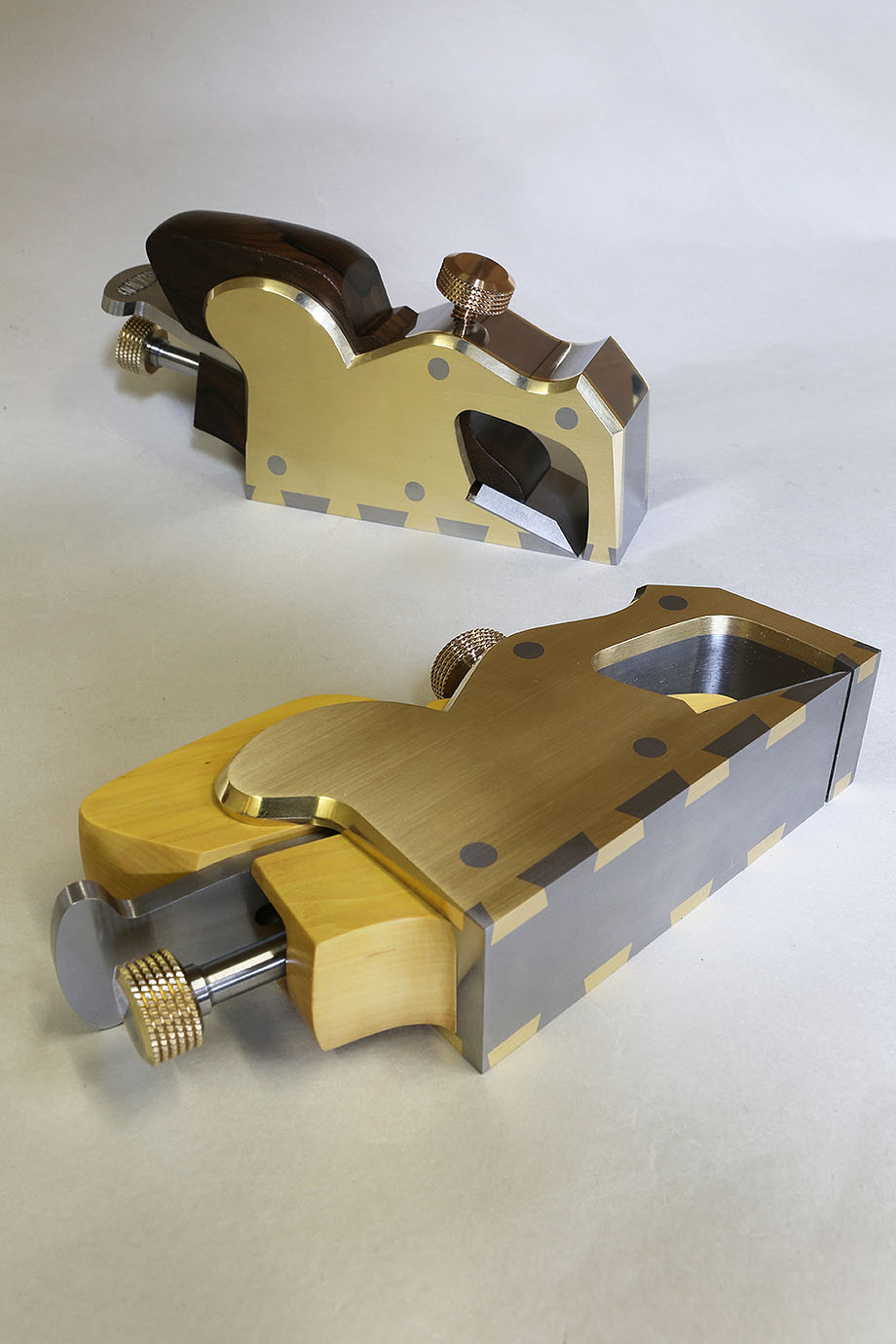

A27 Bullnose plane

At long last these six bullnose planes are complete. It had been my intention to make this plane for a long time and I must confess that this project has been a bit of a vanity exercise.

I am not aware of dovetailing having been used for this type of plane before.

This is a very delicate plane and its use is very specialised - certainly not recommended for the shuttering carpenter! There are only six planes and due to the excessive amount of work it will stay at six. Please see the blog for more details of the making of this plane, though I found little time for photos.

This plane was traditionally a casting and not dovetailed, although I have seen a chariot plane by Spiers that was dovetailed.

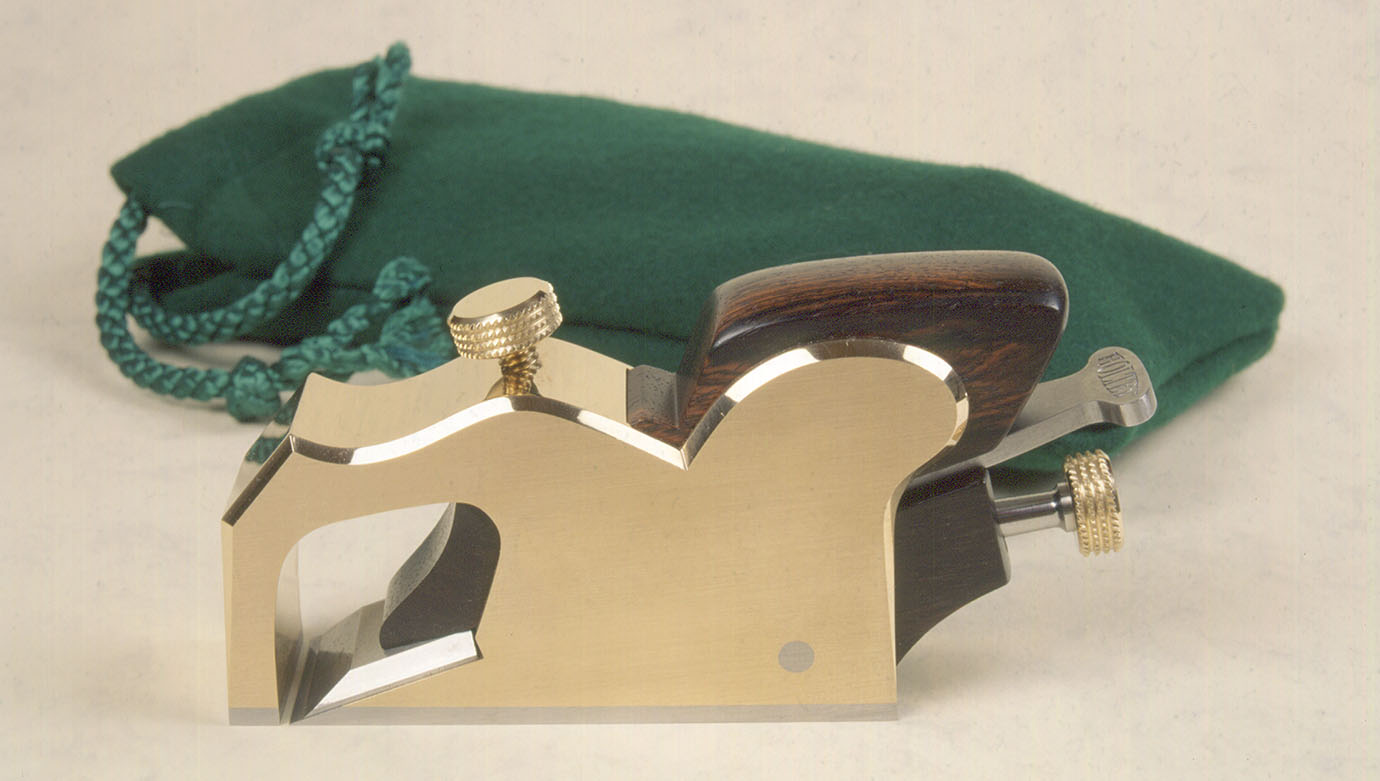

This plane has the advantage of having a badgered mouth on both sides, as on a rebate plane. It can gain greater access due to it's smaller toe. Much sought after by cabinet and instrument makers and was produced by most of the early makers.

It was only Norris that incorporated an adjuster in this style of plane. With its adjuster it makes a very desirable balanced hand tool. These photographs show one of only six planes from my original batch and a couple from my recently completed second batch of just six A27 dovetailed planes.

This is a very delicate plane and its use is very specialised - certainly not recommended for the shuttering carpenter! There are only six planes and due to the excessive amount of work it will stay at six. Please see the blog for more details of the making of this plane, though I found little time for photos.

This plane was traditionally a casting and not dovetailed, although I have seen a chariot plane by Spiers that was dovetailed.

This plane has the advantage of having a badgered mouth on both sides, as on a rebate plane. It can gain greater access due to it's smaller toe. Much sought after by cabinet and instrument makers and was produced by most of the early makers.

It was only Norris that incorporated an adjuster in this style of plane. With its adjuster it makes a very desirable balanced hand tool. These photographs show one of only six planes from my original batch and a couple from my recently completed second batch of just six A27 dovetailed planes.

precision engineering without compromise

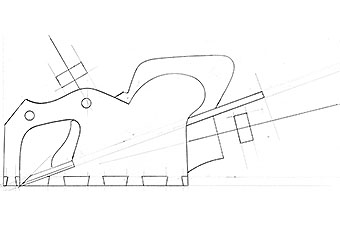

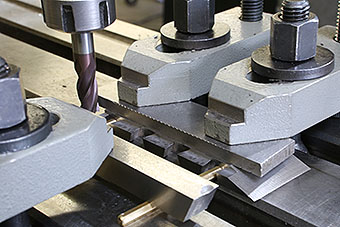

Making the dovetailed A27 Bullnose plane

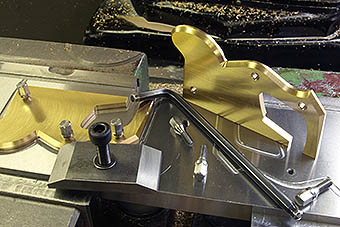

This is the dovetailing on the bottom which is done in a pair so I can work them back to back which is much easier for programming.

When the dovetailing is completed on the bottom I machine a shoulder which provides better support to the sides and is a 'light stop'.

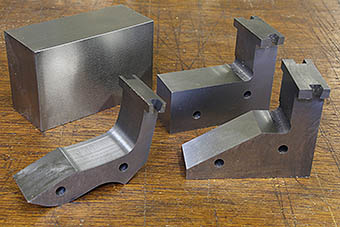

This is the main metal infill for the A27 which has a complex contour so with the limitations of my milling machine I mill on both sides by turning it over to the other side which is then mirrored. With careful setting it works out perfect.

This shows the different stages of machining the metal infill from a solid block and the rest speaks for itself.

The naval brass side after profiling and chamfering. Using a fixture plate which I make for all the different plane sides.

After the profiling and chamfering the throat can be routed out by adding another clamp to the existing fixture for extra support.